Manufacturers are speeding up digital transformation with major data updates that include moving away from legacy systems. Recently, carbon-steel maker Forza Steel announced a move to SAP Cloud ERP on Microsoft Azure. As a result, they outlined an AI-powered data strategy to boost efficiency and industry leadership. Similarly, Brose completed a six-month SAP cloud ERP migration without stopping production. In doing so, they set a new benchmark for minimal downtime and smooth transition.

These cases show a broader shift in manufacturing. In this shift, modern data migration is key to unlocking quick analytics, connected systems, and advanced automation across global operations.

According to industry reports, over 70% of manufacturers are planning large-scale digital updates. Additionally, data migration is a central part of these plans. Companies using AI-enabled migration methods report up to 35% faster system transitions. Furthermore, they see a 40% reduction in errors compared to traditional manual methods. This shows how proper data migration can directly impact production efficiency, cost savings, and operational flexibility.

Continue reading this blog to explore best practices for data migration in manufacturing. Moreover, learn about the tools that make complex system transitions easier. You’ll also discover how manufacturers are unlocking real-time insights and smarter operations through modern data platforms.

Modern Manufacturing Runs On Clean Data

Kanerika is ready to support your migration from start to finish.

Key Takeaways

- Modern manufacturing depends on accurate, connected data. Therefore, legacy system migration is essential for efficiency, analytics, and automation.

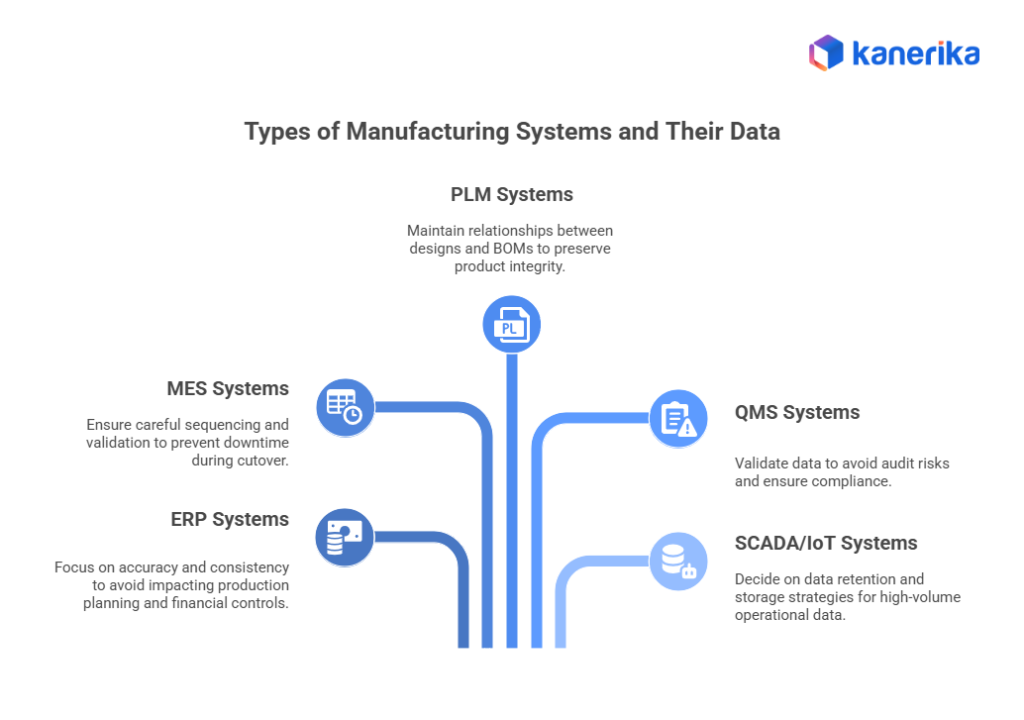

- Data comes from different sources like ERP, MES, PLM, QMS, SCADA, and IoT. As a result, each has unique structures, importance, and migration risks.

- Key challenges include downtime sensitivity, inconsistent master data, poor data quality, historical data handling, and compliance needs.

- Choosing the right migration strategy depends on plant complexity, system importance, and risk tolerance. Options include phased, big bang, coexistence, brownfield, or greenfield approaches.

- Automation and AI improve speed, accuracy, and efficiency in extraction, mapping, and validation. However, human oversight ensures compliance and operational context.

- Measuring success through operational performance, data quality, and user adoption helps ensure smooth migration and long-term manufacturing success.

Why Data Migration in Manufacturing Has Become a Business-Critical Priority

Data migration in manufacturing has become a business-critical priority. This is because modern manufacturing depends on connected, reliable, and timely data. Legacy systems that once supported stable operations now limit visibility. In addition, they slow down decision-making and block digital transformation efforts. As manufacturers adopt automation, analytics, and cloud platforms, updating manufacturing data environments is essential.

Market pressures clearly show why data migration matters in manufacturing. Manufacturers face rising customer expectations, unpredictable supply chains, and increasing regulatory demands. Therefore, these challenges need real-time insights into production, inventory, quality, and supplier performance. Disconnected data systems cannot support this level of responsiveness. As a result, data migration is a foundational step for operational flexibility.

Key Forces Driving the Need for Data Migration

Key forces driving the need for data migration include:

- Demand for real-time visibility across manufacturing and supply chain operations

- Increased use of analytics and digital transformation technologies

- Growing compliance and traceability needs

- Pressure to improve efficiency while reducing operational risk

Broken ERP, MES, PLM, and shop floor systems further add to the problem. Many manufacturers operate multiple systems across plants or regions. Often, this happens because of acquisitions or phased implementations. Shop-floor data is usually separated from enterprise platforms. Consequently, this leads to data silos, inconsistent master data, and duplicated records.

When implementing digital transformation, data is scattered across disconnected systems, and its value drops significantly. In this context, data migration in manufacturing helps bring together systems, standardize data, and create a unified foundation. This foundation supports faster decisions, better coordination, and long-term business strength.

Understanding Manufacturing Data Landscapes Across Plants and Systems

Manufacturing environments create data from multiple systems operating at different business layers. When organizations plan data migration in manufacturing, they often underestimate the differences among these data sources. Moreover, they underestimate how differently each system behaves during migration. Therefore, a clear understanding of the manufacturing data landscape is essential to avoid disruption and data quality issues.

At an enterprise level, systems handle finances and planning. Meanwhile, at the plant level, systems track production, quality, and equipment performance. On the shop floor, machines and sensors continuously create operational data. Manufacturing system connections become challenging when these systems operate in silos. Additionally, challenges arise when they use different data standards or grow independently over time.

Types of Manufacturing Systems and Their Data

Each manufacturing system stores data with specific purposes, structures, and levels of importance. Recognizing these differences helps define the right migration approach.

1. ERP Systems Used for Core Business Operations

ERP platforms such as SAP, Oracle, and Microsoft Dynamics form the backbone of manufacturing operations. They handle highly structured and business-critical data, including:

- Financial transactions and accounting data

- Material masters and inventory records

- Purchase orders and supplier information

Because ERP data supports planning, buying, and financial reporting, accuracy and consistency are non-negotiable. In fact, errors introduced during migration can directly impact production planning and financial controls.

2. Manufacturing Execution Systems Managing Shop Floor Activities

MES platforms operate closer to production. As a result, they capture real-time shop floor data. These systems typically handle:

- Production schedules and work orders

- Shop floor data collection

- Labor tracking and machine use

MES data is tightly linked to plant operations. Therefore, shop-floor data migration requires careful sequencing and validation. This helps avoid downtime or production differences during cutover.

3. Product Lifecycle Management Systems Handling Engineering Data

PLM systems manage product-related information throughout its lifecycle. This includes:

- Product designs and specifications

- Bills of materials

- Engineering change orders

PLM data is a mix of structured records and documents. During data migration in manufacturing, keeping relationships between designs, revisions, and BOMs is critical. In this way, product integrity is maintained.

4. Quality Management Systems Supporting Compliance

QMS platforms store compliance-critical data that must remain traceable and auditable after migration. Typical data includes:

- Inspection records and test results

- Non-conformance reports

- Corrective and preventive action tracking

Even small data gaps in QMS migrations can create audit risks. Therefore, validation and matching are essential.

5. SCADA and IoT Systems Generating Operational Data

SCADA and IoT platforms capture data directly from machines and sensors across the shop floor. This includes:

- Equipment sensor data

- Process parameters

- Environmental monitoring metrics

This data is high-volume, time-series-based, and continuously generated. As a result, migrating historical operational data often involves decisions about keeping, grouping, and long-term storage.

Different Data Types Need Different Migration Approaches

Manufacturing digital transformation data does not exist in a single format. Understanding data types helps determine how migration should be planned and carried out.

Manufacturing data typically falls into three broad categories:

1. Structured Data

This includes traditional database records such as material codes, customer records, inventory balances, and transaction histories. This data follows consistent patterns. Generally, it is easier to map and validate. However, quality issues like duplication and outdated values are common.

2. Semi-Structured Data

This includes engineering documents, quality reports, and equipment manuals. These combine defined fields with unstructured content. Therefore, migrating this data needs preserving context, relationships, and document information to maintain usefulness.

3. Operational Data

This consists of real-time streams from sensors, machines, and control systems. It is created continuously and in massive volumes. Historical operational data can span many years. As a result, this creates challenges related to storage, performance, and relevance during data migration in manufacturing.

Recognizing these differences allows manufacturers to design migration strategies. These strategies protect critical data, support connections to the manufacturing system, and ensure long-term value from modernization efforts.

Manufacturing System Comparison Table

| Manufacturing System Type | Data Characteristics | Migration Risk Level |

| ERP systems | Highly structured master and transactional data | Medium |

| MES platforms | Production and performance data tied to plant processes | High |

| PLM systems | Engineering data with frequent version changes | Medium |

| QMS systems | Compliance and audit data requiring high accuracy | High |

| SCADA systems | Real-time machine and control data | High |

| IoT sensor platforms | High volume time-series operational data | Very High |

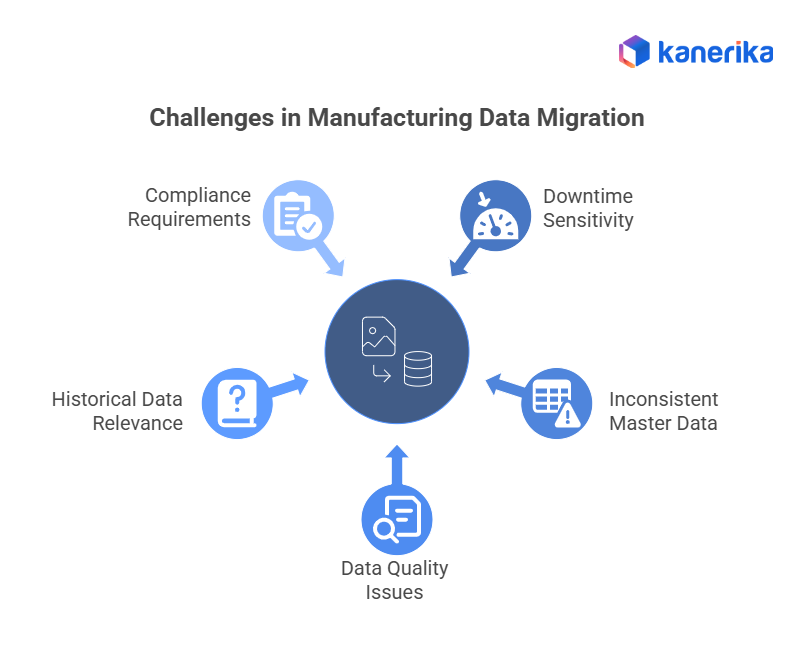

Key Challenges in Manufacturing Data Migration

Data migration in manufacturing is uniquely complex. This is because it directly affects production operations, planning accuracy, and regulatory compliance. Understanding the key challenges helps organizations reduce risk, improve efficiency, and ensure a smooth transition to modern systems.

1. Downtime Sensitivity and Production Disruption

Manufacturing systems operate on tight schedules. Consequently, any unforeseen downtime or data migration error can stop production. In addition, they are able to postpone orders and make operations rather expensive. Consequently, migration activities should be well planned and sequenced. This will maintain real-time production as information is transferred between the ERP and MES, as well as other essential systems.

2. Inconsistent Master Data Across Plants

Most manufacturers have multiple facilities with independent material masters, vendor records, and product codes. These inconsistencies, therefore, result in duplication, poor reporting, and planning. Hence, it is vital to maintain the master data integrity amongst the plants. This ensures consistency in purchasing, manufacturing planning, and financial reporting.

3. Data Quality Issues

Poor-quality data transfer is one of the major reasons for unsuccessful migrations. The most common are duplicate records, inconsistent units of measure, incomplete bills of materials, and old customizations. Moreover, these may be incompatible with contemporary systems. Data cleaning for manufacturing before migration will be performed to ensure systems function as desired. Furthermore, it facilitates proper decision-making.

4. Historical Data Relevance vs Storage Costs

Manufacturers have decades of operational, production, and sensor data. Although historical data is important to analyse and comply with, migrating all of it can increase storage costs and system complexity. Consequently, making a decision about what to archive, retire, or migrate is a very important requirement in planning.

5. Compliance and Traceability Requirements

The manufacturing conditions should be of high quality and in compliance with regulations. The data of inspection records, audit trails, and corrective actions should be accurate and traceable following the migration. As a matter of fact, compliance risks may occur due to any gaps or errors. In addition, they discourage confidence in the new system.

Addressing these five challenges with structured planning, strong data cleaning, and governance creates a solid foundation. Consequently, this leads to successful manufacturing data migration and long-term operational strength.

Data Migration Strategies That Work Best for Manufacturing Organizations

Choosing the right data migration strategy is critical in manufacturing. This is because system data drives production, supply chain, quality, and compliance. Effective strategies ensure minimal disruption, maintain data integrity, and enable smooth transition to modern platforms. These platforms include ERP, MES, PLM, QMS, and shop floor systems.

1. Phased Migration for Gradual Data Transition

Phased migration involves moving manufacturing data in stages. For example, this can be done by a plant, a system module, or a functional area. This approach allows teams to check data migration at each stage before moving forward. It reduces operational risk. Additionally, it is ideal for multi-plant setups where production continuity is critical. Studies show phased data migrations lessen the likelihood of errors by over 30%. This is compared to full-system cutovers.

2. Big Bang Migration for Single-Cutover Transitions

Big bang migration moves all manufacturing data in a single cutover. While this can shorten the overall migration timeline, it carries a higher risk of operational disruption. In fact, errors during a big bang data migration can affect production scheduling, inventory, and reporting immediately. This strategy works best for smaller plants or simpler system environments. In these cases, downtime can be tightly controlled.

3. Coexistence Strategies During Cutover

Coexistence involves running both legacy and target systems concurrently during the migration process. This enables real-time checking of migrated data. Moreover, it ensures continuous manufacturing operations. Coexistence is particularly valuable for shop floor systems and MES data. This is because downtime directly impacts production.

4. Brownfield ERP Data Migration

Brownfield migration updates an existing ERP while keeping historical and operational data. It preserves legacy workflows. However, it needs careful review to ensure older customizations align with modern data structures. This strategy is suited for organizations that need continuity and minimal disruption.

5. Greenfield ERP Data Migration

Greenfield migration implements a completely new ERP system. As a result, it standardizes processes and removes legacy data issues. While it offers the opportunity for clean data and modern system design, it needs careful planning of the data migration cutover. This ensures critical manufacturing data is accurately transferred.

Migration Strategy Comparison Table

Selecting the right strategy ensures a smooth transition of manufacturing system data. Furthermore, it preserves data integrity and supports operational continuity. In doing so, it lays the foundation for long-term efficiency and digital transformation success.

| Migration Strategy | Best Suited Scenario | Risk Level | Downtime Impact |

| Phased Migration | Multi-plant or complex manufacturing systems | Low | Minimal |

| Big Bang Migration | Small plants or simple systems | High | High |

| Coexistence | Critical MES or shop floor data | Medium | Moderate |

| Brownfield ERP | ERP upgrades retaining historical data | Medium | Low to Moderate |

| Greenfield ERP | Full ERP modernization or process redesign | Medium to High | Moderate |

Role of Automation and AI in Modern Manufacturing Data Migration

1. High-Impact Automation Applications

Modern manufacturing data migration benefits significantly from smart automation across several critical areas. Automation delivers measurable value by reducing human error and improving consistency. Additionally, it allows teams to focus on exceptions and business-critical decisions.

Key automation opportunities include:

- Data extraction and transformation processes: Using advanced ETL tools that process massive volumes of structured manufacturing data with minimal human help

- Structured data validation: Through automated scripting that systematically finds duplicates, missing fields, and format inconsistencies before system cutover

- Intelligent data mapping: Using ERP and MES business rules to automatically map legacy fields to target system designs

- Cross-system matching: Identifying critical differences between MES and ERP systems that could cause weeks of post-migration delays

2. Advanced AI Applications in Manufacturing Data Migration

Artificial intelligence brings sophisticated capabilities to the challenges of manufacturing data migration. These are challenges that traditional automation cannot address effectively. Research from McKinsey indicates that AI-assisted manufacturing data migration efforts can reduce overall engineering effort by up to 40%. At the same time, they improve data accuracy and migration success rates.

AI delivers breakthrough abilities through:

- Legacy code interpretation: Enabling AI tools to read complex custom scripts, proprietary macros, and embedded system logic. As a result, this extracts critical transformation rules.

- Intelligent problem detection: Using machine learning models to identify subtle inconsistencies in BOMs, routing data, and sensor streams. These are inconsistencies that conventional validation methods miss.

- Predictive field mapping: Analyzing historical data patterns to suggest optimal field mappings between legacy and target systems. This is based on learned relationships and industry best practices.

- Pattern recognition: For complex manufacturing workflows that improve data transformation accuracy and validation processes.

3. Critical Areas Requiring Human Expertise and Oversight

Despite significant automation abilities, certain manufacturing data migration aspects need experienced human judgment and oversight. This ensures compliance and operational success. The most effective manufacturing data migration strategies combine automation for scale and efficiency. Moreover, they combine it with strategic human oversight for accuracy, compliance, and business context validation.

Critical areas requiring human know-how include:

- Compliance-critical data validation: For inspection records, corrective action documentation, and regulatory compliance data. This demands complete accuracy and traceability.

- Complex product lifecycle management: Involving detailed decisions about BOM revisions, engineering change orders, and product configuration data. This requires deep manufacturing know-how.

- Plant-specific operational rules: And manufacturing workflows with unique customizations and exception handling. These require human interpretation.

- Business context validation: Ensuring that automated transformations align with operational needs and industry-specific practices.

How BI Migration for Manufacturing Organizations Drives Growth

BI migration helps manufacturers streamline data, improve decision-making, and modernize systems for faster, clearer operations.

Governance, Security, and Compliance Excellence

The success of manufacturing data migration depends heavily on strong governance frameworks. These frameworks ensure data integrity, security, and regulatory compliance throughout the entire process.

1. Comprehensive Data Lineage and Audit Capabilities

Establishing complete data lineage documentation ensures every manufacturing record can be traced. This trace goes from the original source through the final target system implementation. In addition, detailed audit trails of migration activities provide essential accountability. They also enable validation of complex data transformations.

This documentation becomes particularly critical in regulated manufacturing environments. These include aerospace, automotive, pharmaceutical, and food and beverage industries. In these industries, regulatory compliance requires complete traceability.

2. Role-Based Access Control and Validation Workflows

Implementing strict role-based access controls prevents unauthorized changes during critical migration phases. Moreover, structured approval workflows ensure that qualified manufacturing experts validate and approve data transformations before implementation.

These security measures reduce human error. At the same time, they create auditable migration processes. These processes show compliance with internal governance standards and external regulatory needs.

3. Change Management and Stakeholder Communication

Effective governance extends beyond technical controls. It also includes comprehensive change management and stakeholder communication strategies. Manufacturing data migration impacts multiple departments. These range from production and quality to finance and supply chain. Therefore, this requires coordinated communication plans.

Establishing clear problem-solving procedures, regular stakeholder updates, and cross-functional communication methods ensures migration decisions consider operational impacts. Consequently, this happens across the entire manufacturing organization. Furthermore, it builds confidence in the process.

4. Data Encryption and Security Protocols

Manufacturing data often contains sensitive intellectual property, proprietary formulations, and competitive operational insights. As a result, this requires comprehensive protection during migration. Implementing strong security methods protects critical business information while maintaining access.

Essential security measures include:

- End-to-end encryption for data in transit and at rest during migration processes

- Secure communication channels between legacy and target systems to prevent interception

- Regular security checks identify weak points throughout migration phases

- Backup and recovery methods ensure protection against system failures or incidents

5. Industry-Specific Compliance Requirements

Manufacturing organizations must navigate complex regulatory landscapes. These require specific attention to data quality traceability, inspection recordkeeping, and compliance metric validation. This happens throughout migration processes. Documented checking procedures, formal approval workflows, and comprehensive validation reports serve as essential trust signals. They serve this purpose for auditors, regulatory agencies, and internal stakeholders. In doing so, they show strict adherence to governance and compliance standards.

How to Measure Success After Data Migration in Manufacturing

Measuring the success of manufacturing data migration requires a comprehensive approach. This approach tracks both technical achievements and business outcomes. Effective measurement frameworks distinguish between different types of performance indicators. At the same time, they establish clear benchmarks for ongoing validation and continuous improvement.

1. Operational KPIs vs Data Quality KPIs

A. Operational Key Performance Indicators

Operational Key Performance Indicators focus on business continuity and operational efficiency improvements. These improvements result from successful data migration. These metrics show whether the migration delivers tangible business value. Additionally, they show whether it supports manufacturing excellence.

Critical operational KPIs include:

- Production uptime percentage: Measuring system availability and manufacturing continuity after migration

- On-time delivery performance: Validating that scheduling and planning data accuracy supports customer commitments

- Inventory turnover rates: Confirming that material master data enables effective supply chain improvement

- Overall equipment effectiveness (OEE): Ensuring that migrated machine and production data support operational efficiency

- Cost per unit production: Showing whether data accuracy improvements translate to operational cost reductions

B. Data Quality Key Performance Indicators

Data Quality Key Performance Indicators measure the technical accuracy, completeness, and integrity of migrated manufacturing data. These metrics validate that the migration process successfully transformed and validated critical business information.

Essential data quality KPIs include:

- Data completeness rates: Measuring the percentage of successfully migrated records across all manufacturing systems

- Duplicate record removal: Measuring reduction in data redundancy and inconsistencies

- Data accuracy validation: Confirming the correctness of BOMs, routing information, and master data elements

- Historical data integrity: Ensuring traceability and auditability of production records and quality data

- Cross-system data consistency: Validating alignment between ERP, MES, PLM, and QMS systems

2. Adoption Metrics from Plant Users

User adoption represents a critical success factor. This factor determines whether data migration delivers operational value. Manufacturing environments require high user confidence in system reliability and data accuracy. This maintains production efficiency and safety standards.

Key adoption metrics to track include:

- Active user engagement rates: Measuring daily system use across different plant functions and shifts

- Training completion percentages: Ensuring plant personnel receive adequate preparation for new systems and processes

- User satisfaction scores: Gathering feedback on system ease of use, data access, and reporting abilities

- Reduction in manual workarounds: Measuring decreased reliance on spreadsheets, paper records, and offline processes

- Help desk ticket volume: Monitoring support requests and system-related issues reported by plant users

- Time-to-productivity metrics: Measuring how quickly plant personnel achieve full operational efficiency with migrated systems

3. Post-Migration Reconciliation and Validation Benchmarks

Comprehensive matching processes provide essential validation. This validation shows that data migration achieved intended outcomes while maintaining operational integrity. These benchmarks establish ongoing monitoring frameworks. In turn, these frameworks support continuous improvement and compliance checking.

Critical matching benchmarks include:

- Legacy vs target system validation: Conducting systematic cross-checks to verify data accuracy and completeness across all migrated datasets

- Exception resolution timeframes: Measuring speed and effectiveness of addressing data differences and migration-related issues

- Compliance audit results: Showing regulatory adherence and traceability needs for manufacturing quality standards

- Business process continuity metrics: Validating that migrated data supports uninterrupted manufacturing workflows and decision-making processes

- Financial matching accuracy: Ensuring that cost accounting, inventory valuation, and financial reporting remain consistent and accurate

Benchmark Timeline Expectations

- Week 1-2 Post-Migration: Complete initial data validation and address critical exceptions

- Month 1: Achieve 95% user adoption and resolve major workflow disruptions

- Month 3: Show measurable improvements in operational KPIs and data quality metrics

- Month 6: Complete comprehensive compliance audits and establish baseline performance for future improvements

Successful manufacturing data migration efforts establish these measurement frameworks before migration begins. Consequently, this enables proactive monitoring and rapid issue resolution. Furthermore, this supports both operational continuity and long-term digital transformation goals.

Pre-Migration vs Post-Migration Success Metrics Table

| Metric Category | Before Migration | After Migration Target |

| Production Uptime | 92% | 98% |

| Inventory Accuracy | 85% | 98% |

| BOM Accuracy | 82% | 99% |

| Duplicate Records | 15-20% | <2% |

| User Adoption | 65% | 95% |

| Manual Reconciliation | 40 hrs/week | 5 hrs/week |

| Data Validation | Manual | Automated 99.5% |

Kanerika’s Manufacturing Data Migration Approach for Power BI and Microsoft Fabric

Manufacturing data is spread across ERP systems, MES systems, historians, IoT platforms, and Excel-based plant reports. ERP systems manage production orders and material movements, MES captures machine events and operator inputs, and supervisors often rely on spreadsheets for scrap and downtime tracking. This fragmented landscape slows decision-making and limits real-time operational insight.

Kanerika helps manufacturers build connected data ecosystems by migrating operational and analytical data into Power BI and Microsoft Fabric. The goal is to create a unified analytics backbone for OEE, downtime intelligence, and quality analytics, without disrupting plant operations.

A. SSRS to Power BI Migration Powered by FLIP

Manufacturing plants often depend on extensive SSRS report libraries built over many years. These reports contain critical business logic for production KPIs, downtime classification, and quality metrics. Rebuilding them manually increases risk and slows modernization.

Kanerika uses its proprietary FLIP platform to accelerate SSRS to Power BI migration by:

- Parsing RDL files to extract queries, parameters, and embedded logic

- Preserving existing KPI calculations used on the shop floor

- Rebuilding reports in Power BI with interactive visuals and faster refresh

FLIP automates a large portion of report conversion, reducing migration time while ensuring trusted calculations remain intact.

B. Microsoft Fabric Architecture Designed for Manufacturing Data

Kanerika applies a manufacturing-focused Fabric architecture that unifies ERP, MES, historian, IoT, and Excel data within structured lakehouse zones. This architecture is built specifically around manufacturing KPIs rather than generic analytics models.

Key elements include:

- Predefined Fabric data models for OEE, downtime, scrap, defects, and throughput

- Standardized handling of shift calendars, plant hierarchies, and machine states

- Scalable storage for both historical and near-real-time plant data

This gives manufacturers a consistent foundation for analytics across lines and plants.

C. ERP and MES Schema Alignment with FLIP Validation

Inconsistent ERP and MES data definitions often distort manufacturing KPIs. Differences in work center names, timestamps, and machine identifiers reduce confidence in analytics.

Kanerika addresses this using FLIP-enabled validation by:

- Aligning ERP and MES schemas into a unified data pattern

- Standardizing identifiers and time logic across systems

- Validating migrated datasets against source systems to ensure accuracy

This ensures OEE and downtime metrics remain consistent and trustworthy post-migration.

D. End-to-End Fabric Pipelines for Plant Data

Kanerika builds Fabric pipelines that ingest equipment readings, production orders, quality checks, and operator inputs. FLIP supports pipeline modernization by accelerating transformations and reducing manual effort.

These pipelines:

- Clean time gaps and merge cross-system events

- Automate ingestion and transformation workflows

- Enable near real-time visibility into plant performance

By combining Power BI, Microsoft Fabric, and FLIP, Kanerika enables manufacturers to move from fragmented reporting to reliable, real-time insight that supports continuous improvement and predictive decision-making.

BI Modernization: How to Migrate from Legacy BI Tools in 2025

Explore BI modernization strategies to improve analytics and decision-making.

Kanerika Enables Seamless Manufacturing Data Migration with Automation and AI

Kanerika helps manufacturing organizations update their data structure and analytics. We do this by delivering fast, secure, and smart data migration strategies. Legacy manufacturing systems often struggle with large, complex datasets. Additionally, they struggle with broken ERP/MES/PLM data and real-time reporting needs. Therefore, Kanerika’s approach ensures a smooth transition to modern platforms. Moreover, this happens without disrupting ongoing operations.

Our End-to-End Migration Services

We provide complete migration services across multiple areas:

- BI Migration: Move from legacy tools like Tableau, Cognos, SSRS, and Crystal Reports to Power BI for interactive dashboards and real-time insights.

- Data Warehouse to Data Lake Migration: Shift from rigid warehouse setups to flexible data lakes or lakehouse platforms for handling structured, semi-structured, and unstructured data.

- Cloud Migration: Transition workloads to secure, scalable environments such as Azure or AWS for better performance and cost efficiency.

- ETL and Pipeline Migration: Modernize data pipelines for faster ingestion, transformation, and orchestration.

- RPA Platform Migration: Upgrade automation infrastructure from UiPath to Microsoft Power Automate for streamlined workflows.

Our proprietary platform, FLIP, speeds up these migrations with Smart Migration Accelerators. FLIP automates up to 80% of the migration process. As a result, it reduces risk, preserves business logic, and enables manufacturers to adopt cloud-native, AI-ready setups in weeks instead of months. It handles complex transitions such as Tableau → Power BI, SSIS → Microsoft Fabric, and Informatica → Talend. Furthermore, it ensures zero data loss and operational continuity.

Kanerika ensures compliance with global standards throughout the migration process. These standards include ISO 27001, ISO 27701, SOC 2, and GDPR. By combining know-how in automation, AI, and cloud engineering, Kanerika empowers manufacturers. Consequently, they can unlock predictive insights, improve production efficiency, and build a future-ready, strong data structure.

Reliable Data Migration Supports Better Operations

Kanerika will help you move your data the right way.

FAQs

1. What is data migration in manufacturing?

Data migration in manufacturing is the process of moving data from legacy systems such as ERP, MES, or SCADA into modern platforms. This includes production data, inventory records, supplier information, and quality metrics. The goal is to ensure data remains accurate, usable, and accessible for operational and analytical needs.

2. Why is data migration important for manufacturing companies?

Manufacturers rely on data to manage production schedules, quality control, and supply chains. Poor data migration can lead to downtime, incorrect planning, and compliance risks. A well executed migration improves visibility, supports automation, and enables better decision making across manufacturing operations.

3. What are the common challenges in manufacturing data migration?

Manufacturers often face issues like inconsistent data formats, duplicate records, and outdated legacy systems. Integrating data from multiple plants and systems adds complexity. Without proper validation and testing, these challenges can result in data loss or operational disruptions.

4. Which manufacturing systems are typically involved in data migration?

Common systems include ERP for finance and inventory, MES for production tracking, PLM for product data, and quality management systems. Data may also come from IoT devices and machine logs. Migrating data across these systems requires careful mapping and validation.

5. How can manufacturers reduce risks during data migration?

Risk can be reduced by cleaning and validating data before migration, involving business users for accuracy checks, and running multiple test migrations. Using phased migration approaches and maintaining backups also helps minimize downtime and data loss.

6. How long does a manufacturing data migration typically take?

The timeline depends on data volume, number of systems, and data quality. Small migrations may take a few weeks, while complex enterprise migrations can take several months. Early planning and stakeholder involvement help keep timelines predictable.