Supply chain automation is using technology to manage and streamline supply chain processes, reducing human intervention and increasing efficiency. Henry Ford revolutionized the manufacturing concept by introducing the assembly line into his automobile factories, laying the groundwork for large-scale manufacturing automation.

This historic innovation began a relentless pursuit of efficiency and productivity through technology, fundamentally transforming how products are created, managed, and delivered. Today, the evolution of supply chain automation has expanded far beyond the factory floor, encompassing the automation of material flow, information transfer, financial transactions, and the intricacies of relationships with suppliers and customers.

The drive towards automation now leverages data, the internet, AI, IoT, etc. to enhance intercompany and company-to-customer collaborations. As we explore the significant strides made in supply chain automation in the 21st century, it’s crucial to recognize the pivotal role of such technologies in shaping the future of global supply chains.

With the global supply chain management market expected to grow from USD 25.74 billion in 2022 to around USD 72.1 billion by 2032, the ongoing technological transformation is not just a trend but a critical investment for companies aiming to thrive in an increasingly competitive and interconnected world.

Fundamentals of Supply Chain Automation

Supply chain automation refers to using technology to manage and streamline various aspects of the supply chain process. Your goal is to increase efficiency and reduce manual intervention.

Key Components

1. Software Systems

Utilize Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) software to gain a real-time view of the supply chain.

2. Hardware Technologies

Embed sensors and use robotics to improve warehousing and transportation.

Benefits

- Efficiency: Streamline operations and reduce time-consuming tasks

- Accuracy: Minimize human error and enhance data precision

- Cost Savings: Optimize resource usage and inventory levels

Process Automation Examples

- Order Processing: Automate customer orders to fulfillment

- Inventory Management: Use intelligent systems to track and reorder stock

- Transportation Management: Implement systems for route optimization and shipment tracking

Integrating these technologies seamlessly with your current processes is imperative to ensure a cohesive supply chain network. Early investment in supply chain automation can position you competitively by adapting rapidly to market changes and customer needs.

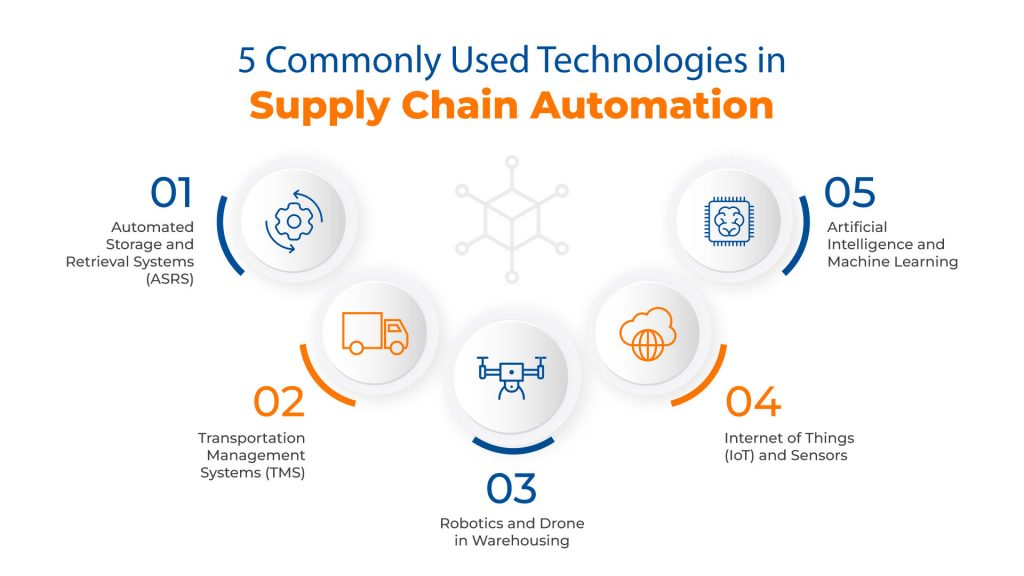

Technology in Supply Chain Automation

Advancements in technology are reshaping how supply chains operate. Your knowledge of these systems is critical for modern logistics performance.

Automated Storage and Retrieval Systems (ASRS)

Automated Storage and Retrieval Systems (ASRS) are integral to warehouse efficiency. These systems save space and expedite inventory retrieval by using software-controlled machines that place and retrieve loads from designated storage locations.

Transportation Management Systems (TMS)

Transportation Management Systems (TMS) streamline the shipping process. They optimize route planning, track shipments in real time, and reduce freight costs through efficient carrier management. Utilizing a TMS can significantly impact your bottom line by saving time and resources.

Robotics and Drones in Warehousing

Warehouses increasingly rely on robotics and drones. Robots handle repetitive tasks such as picking and packing, while drones offer inventory checks at heights and in hard-to-reach places. These technologies accelerate processes and reduce human error.

Internet of Things (IoT) and Sensors

IoT and sensors provide real-time data tracking, essential for inventory management and predictive maintenance. Sensors in machinery, vehicles, and cargo give you visibility into every stage of the supply chain, allowing for proactive adjustments and improved decision-making.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) algorithms analyze vast amounts of data, predicting supply chain disruptions before they occur. Your use of AI and ML in forecasting, demand planning, and logistics optimization can create a competitive edge by anticipating market changes and responding effectively.

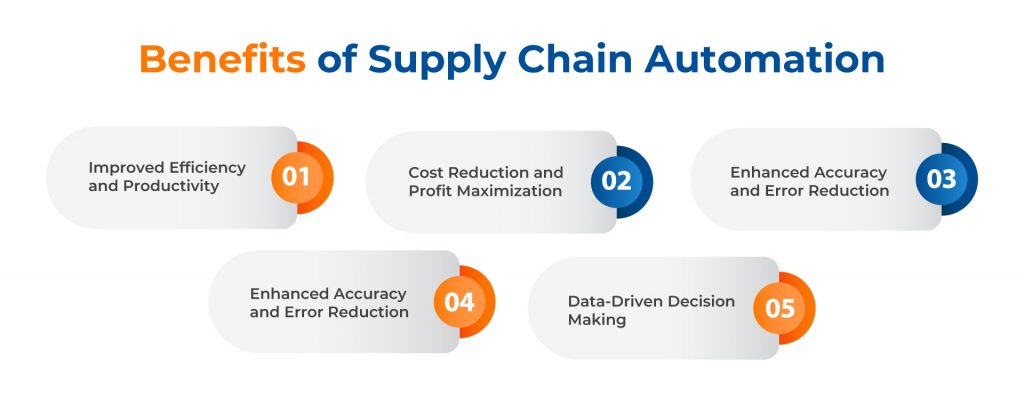

Benefits of Supply Chain Automation

Automating your supply chain can significantly streamline operations. Here’s how it can specifically benefit your organization:

Improved Efficiency and Productivity

You can expect a marked increase in efficiency and productivity with automation. Systems can run 24/7, eliminating downtimes and boosting output. For example, order processing speeds increase as manual entry is replaced with automated solutions that operate around the clock.

Cost Reduction and Profit Maximization

Implementing automation will minimize labor costs and reduce expenses associated with manual errors and inefficiencies. Greater control over inventory leads to decreased excess stock and related holding costs, directly impacting your profit margins.

Enhanced Accuracy and Error Reduction

Your accuracy in order fulfillment will improve, as automated systems are less prone to error than human counterparts. Inventory management software can precisely track and manage stock levels, leading to fewer stockouts or surplus inventory.

Data-Driven Decision Making

You’ll gain the ability to make informed decisions based on real-time data and analytics. Automated tools can provide actionable insights through data collection and analysis, helping you optimize your supply chain for better performance.

Implementation Strategies

Effective implementation of supply chain automation requires thorough planning, strategic process reengineering, and proactive staff training with a strict focus on managing change across the organization.

Assessment and Planning

Before you deploy supply chain automation, conduct a comprehensive assessment of your current processes. Identify bottlenecks and inefficiencies that automation can address. Develop a clear roadmap which includes:

- Goals: Establish specific, measurable objectives

- Timeline: Outline a realistic schedule for deployment

- Resources: Allocate the necessary financial and human resources

Process Reengineering

Redesign your supply chain processes to optimize the integration of automation technologies. Evaluate each stage of your supply chain for improvement by:

- Creating process flowcharts

- Analyzing the potential impact of automation

- Adjusting workflow to accommodate new technologies

Staff Training and Change Management

Prepare your team for the transition through targeted training programs and effective change management strategies. Ensure successful adoption by:

- Developing Skills: Train staff on new systems and technologies

- Communication: Keep open and transparent communication channels

- Support Structures: Implement support systems to address concerns and feedback

Challenges and Considerations in Supply Chain Automation

Implementing supply chain automation comes with a set of challenges that require careful planning and strategic consideration to avoid potential pitfalls and to ensure the system operates as intended.

Integration with Existing Systems

Your current infrastructure may need significant adjustments to accommodate new automation technologies. Seamless integration is critical for realizing efficiency gains. Key issues include compatibility with legacy systems, data migration, and synchronization across different platforms.

Data Security and Privacy

Automated systems handle vast amounts of sensitive data. Ensuring the protection of this data is paramount. You need to address vulnerabilities to prevent breaches, adhere to regulatory requirements, and maintain trust in your supply chain.

Critical areas:

- Encryption protocols

- Access controls

- Regulatory compliance

Scalability and Flexibility

The automation solution you select must be able to scale with your business needs. Scalability pertains to both the handling of increased volume and the capacity to integrate new functions. Flexibility is essential for adapting to market changes and technological advancements without significant overhauls.

Scalability factors include:

- System architecture

- Software and hardware capabilities

Flexibility may involve:

- Modular components

- Configurable software

Supplier and Partner Collaboration

Successful supply chain automation extends beyond your internal operations to encompass suppliers and partners. Your automated systems must facilitate real-time collaboration and information sharing, streamlining processes, reducing errors, and improving response times.

Collaboration considerations:

- Data exchange standards

- Communication protocols

Innovation and Future Trends

In this era, your supply chain can significantly benefit from the latest advancements in technology. Here, we explore the cutting-edge tools and practices that are reshaping supply chain management.

Predictive Analytics and Demand Forecasting

You’ll notice how predictive analytics are transforming the landscape of supply chain planning. These systems utilize machine learning algorithms and big data to anticipate market trends and consumer demand with striking accuracy.

- Big Data Sources: Sales history, weather patterns, social media trends

- Benefits: Improved stock management, optimized inventory levels, reduced waste

Blockchain for Transparency

Blockchain technology is your ally in achieving supply chain transparency and security. By recording transactions in a tamper-proof ledger, you can track the provenance and journey of products with unmatched precision.

Features:

- Decentralization: Eliminates the need for intermediaries

- Traceability: Records every transaction or product movement

Uses:

- Counterfeit prevention

- Compliance verification

Advanced Robotics and Automation

Robotic process automation (RPA) and smart machines are revolutionizing warehouse operations. Your business can increase efficiency and reduce human error with robots capable of picking, packing, and sorting autonomously.

- Implementations: Automated guided vehicles (AGVs), Intelligent picking systems

- Advantages: Faster throughput, enhanced safety, 24/7 operation

Sustainability and Green Logistics

As you pivot to a more sustainable business model, green logistics emerge as a critical component. This encompasses efforts to minimize environmental impact through the adoption of eco-friendly practices and technologies.

Methods:

- Use of alternative fuels.

- Investment in energy-efficient facilities.

Results:

Carbon footprint reduction, cost savings, compliance with environmental regulations

The Path Ahead Priority for Supply Chain Leaders

For supply chain leaders navigating the complexities of the modern business environment, the future is defined by a critical set of priorities: resilience, agility, and digital transformation. These priorities reflect the lessons learned from recent global disruptions and the increasing pace of technological advancement. Leaders are now tasked with building supply chains that can withstand unforeseen challenges, adapt rapidly to change, and leverage digital innovations to maintain competitive advantage.

Kanerika – Driving The Future for Supply Chain Automation

Kanerika is at the forefront of driving innovation in supply chain automation, harnessing the power of data analytics, digital transformation, Robotic Process Automation (RPA), and Artificial Intelligence (AI) to redefine the efficiency and resilience of supply chains.

By deploying advanced data analytics, Kanerika enables businesses to delve into the intricacies of their supply chain operations, uncovering insights that lead to more informed decision-making and strategic planning. This deep dive into data not only optimizes inventory levels and reduces waste but also predicts future trends with remarkable accuracy, enhancing the supply chain’s responsiveness to market changes.

Through digital transformation initiatives, Kanerika integrates cutting-edge technologies to automate and streamline processes, achieving a notable increase in operational efficiency. For instance, the implementation of RPA has allowed businesses to automate repetitive tasks, resulting in up to a 50% reduction in processing times.

Meanwhile, AI and machine learning algorithms are utilized to forecast demand, optimize routes, and manage supplier relationships, driving significant improvements in delivery times and customer satisfaction.

Companies partnering with Kanerika have witnessed remarkable outcomes, such as a 30% improvement in overall supply chain efficiency and a 25% reduction in operational costs. By leveraging Kanerika’s expertise, organizations are not only able to navigate the complexities of today’s global supply chains but are also well-equipped to lead in the future landscape of supply chain management.

FAQs

What is supply chain automation?

Supply chain automation uses technology to streamline and optimize every step, from raw materials sourcing to final product delivery. It’s about replacing manual processes with automated systems to boost efficiency, accuracy, and speed. This reduces human error and allows for better prediction and management of the entire flow of goods and services. Ultimately, it’s about making the whole supply chain smarter and more responsive.

What are the 5 types of supply chain?

There isn’t a universally agreed-upon five-type classification of supply chains. Instead, supply chains are better understood as varying along a spectrum of characteristics, such as their level of integration (e.g., vertically integrated vs. decentralized), agility (responsive vs. efficient), and the nature of their customer relationships (e.g., mass market vs. customized). Focusing on these dimensions is more insightful than trying to fit them into arbitrary categories. Ultimately, the “type” depends on the specific business and its strategy.

What are the benefits of automated SCM?

Automated SCM drastically reduces human error in software development, leading to more reliable and consistent code releases. It frees up developer time, allowing them to focus on creative problem-solving rather than repetitive tasks. This efficiency boosts overall team productivity and accelerates the entire software development lifecycle. Finally, automated systems improve traceability and auditing, enhancing project management and compliance.

What is the role of RPA in supply chain?

RPA streamlines repetitive supply chain tasks, freeing human workers for more strategic roles. It automates things like order processing, invoice management, and data entry, boosting efficiency and accuracy. This ultimately leads to faster delivery times, reduced errors, and improved overall supply chain visibility. Essentially, RPA acts as a tireless, precise worker handling the mundane, allowing humans to focus on complex problem-solving.

What are the 5 supply chain flows?

The five supply chain flows aren’t just about physical goods; they’re interconnected streams of activity. You have product flow (the obvious movement of goods), information flow (tracking and communication), finance flow (payments and credit), and service flow (maintenance and support). Finally, decision flow guides strategy across all these, ensuring smooth operations.

What is the best supply chain software?

There’s no single “best” supply chain software; the ideal solution depends entirely on your business size, needs, and existing systems. The best approach is to identify your biggest pain points (e.g., inventory management, logistics) and find software that specifically addresses those. Consider cloud-based options for scalability and integration capabilities. Ultimately, the best software is the one that improves your efficiency and profitability.

What is SCM workflow?

A Supply Chain Management (SCM) workflow details the step-by-step process of getting a product from raw materials to the end customer. It encompasses everything from sourcing and manufacturing to logistics and sales, orchestrating a seamless flow of information and goods. Optimizing this workflow boosts efficiency, reduces costs, and enhances customer satisfaction. Essentially, it’s the blueprint for a company’s entire product journey.

What is use of AI in supply chain?

AI revolutionizes supply chains by predicting demand fluctuations, optimizing logistics (routing, warehousing), and proactively identifying potential disruptions. This leads to reduced costs, improved efficiency, and enhanced responsiveness to market changes. Essentially, AI helps companies move goods faster, cheaper, and with fewer surprises. It’s about making the entire process smarter and more resilient.

What do you mean by automation?

Automation means using technology to do tasks automatically, without constant human intervention. It’s about replacing repetitive or predictable human actions with machines or software. This boosts efficiency and productivity, freeing up humans for more complex or creative work. Essentially, it’s all about streamlining processes for better results.

What are the issues with supply chain automation?

Supply chain automation, while promising efficiency, faces hurdles. Integrating diverse legacy systems is complex and costly. Unexpected disruptions, like natural disasters or geopolitical events, can expose vulnerabilities in automated systems that weren’t considered. Finally, achieving true end-to-end automation requires overcoming the challenge of managing unpredictable human elements within the supply chain.

What is RPA in SCM?

In Supply Chain Management (SCM), Robotic Process Automation (RPA) is like having a tireless, accurate digital worker. It automates repetitive, rule-based tasks – freeing up human employees for more strategic work. Think invoice processing, order entry, or data reconciliation; RPA handles it all with speed and precision, boosting efficiency and reducing errors. Essentially, it’s about streamlining the *back-office* of SCM for better overall performance.