Have you ever wondered why Data Migration in Automotive has become a strategic priority for manufacturers and mobility leaders? With connected vehicles set to generate massive volumes of data and potentially hundreds of petabytes from sensors and telematics alone as traditional systems simply cannot keep up with today’s demands. In fact, global automotive vehicle services are forecast to grow significantly, with the market expected to reach over $200 billion by 2030, highlighting the importance of data readiness.

The current state of the automotive industry can be characterized by the blistering transition to connected, electric, and software-defined vehicles. This revolution has also resulted in the unleashing of information on the other side of the manufacturing lines, dealer systems, sensors in vehicles and contact with customers, which brings in opportunity and complexity. The old systems, which were never meant to be scaled that large or have such real-time requirements, are now collapsing to perform, have silos of data and cannot be easily integrated.

Subsequently, automotive businesses are resorting to data migration as a principal element of their digital transformation. By moving structured and unstructured data from outdated platforms to modern, cloud-ready systems, organizations can unlock advanced analytics, improve operational efficiency, and fuel innovation across engineering, production, and customer experience. Ultimately, successful data migration enables automotive companies to harness their data for strategic advantage in a competitive, technology-driven future.

Key Learnings

- Automotive data migration is essential for modernization – Legacy ERP, MES, and PLM systems cannot support today’s connected, electric, and software-defined vehicles. Data migration enables automotive organizations to modernize analytics and operations.

- Cloud-native platforms unlock real-time automotive insights – Migrating automotive data to cloud and lakehouse platforms improves performance, scalability, and access to real-time production and vehicle insights.

- Automation and AI reduce migration risk and timelines – AI-driven migration accelerators significantly reduce manual effort while preserving business logic and data accuracy across complex automotive systems.

- Governance and security are critical in automotive migrations – Strict compliance with global standards ensures protection of intellectual property, manufacturing data, and customer information throughout migration.

- A future-ready data foundation drives competitive advantage – Well-executed data migration enables predictive analytics, improved quality control, and faster innovation across the automotive value chain.

Make Your Migration Hassle-Free with Trusted Experts!

Partner with Kanerika for Expert Data Modernization Services

Role of Data Migration in Automotive Industry

Connected vehicles, manufacturing processes, and supply chain operations in the automotive industry produce tremendous volumes of data. In turn, the strategic data migration approaches have gained importance in digital transformation and competitive advantage-seeking automotive companies.

Understanding Automotive Data Migration

First, data migration in the automotive industry is the transfer of vehicle telemetry, manufacturing data, customer and IoT sensor data between systems. This process, in turn, allows the automotive organizations to upgrade the old infrastructure and operate uninterrupted.

Furthermore, automotive data migration is inclusive of all production line data to the connected car analytics which has demands that are industry specific and thus demands special approaches.

Migration Pathways and Platforms

Also, automotive companies are moving away at a steady pace to cloud-based solutions to gain greater scalability and the ability to conduct real-time analytics. Thus, the migration of the cloud allows managing the streams of vehicle data and predictive maintenance even better.

Moreover, modernization of legacy systems will enable car manufacturers to exploit the use of advanced analytics in the development of autonomous vehicles as well as in smart manufacturing projects.

Data Type Considerations

Automobile organizations, in the meantime, process both structured data of the ERP systems and unstructured information of the vehicle sensors and cameras. Nonetheless, unstructured data migration would demand specialized software that would be able to handle video feeds, sensor records, and diagnostic material.

Strategic Modernization Impact

Lastly, data migration facilitates digital transformation efforts in the automotive industry such as connected cars, smart maintenance environments, and optimization of supply chains.

As a result, effective automotive data move facilitates autonomous car engineering, customer experiences, manufacturing efficiency, and adherence to automotive industry rules and regulations as well as safety standards.

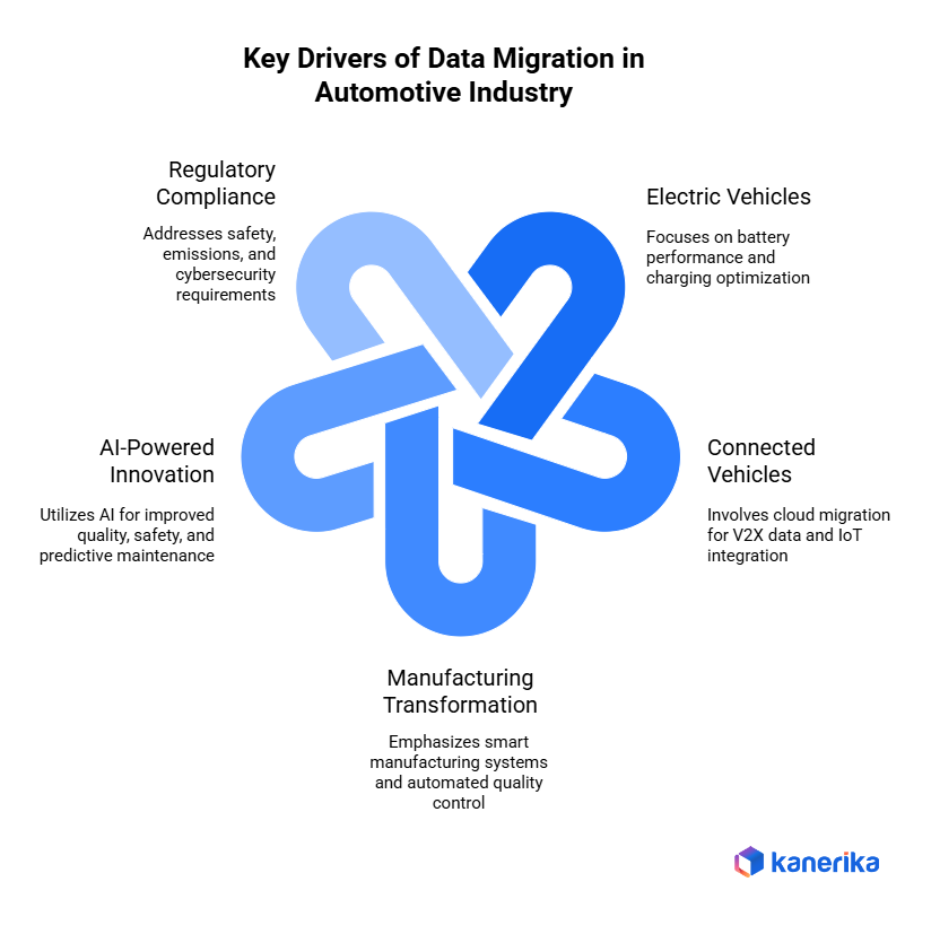

Key Drivers of Data Migration in Automotive Industry

The automotive firms are under more pressure than ever to modernize data infrastructure as the automobile technology develops at a pace that is ever-changing. Therefore, strategic data migration programs can help manufacturers to capitalize on new technologies with the aim of addressing the changing consumer requirements and regulatory standards.

1. Revolution in Electric Vehicles

To start with, the adoption of electric vehicles results in colossal data migration needs in the performance monitoring of batteries and optimization of the charging process. Next, car companies move over to older systems to accommodate real-time battery monitoring systems, thermal control data, and the integration of charging facilities.

Besides, EV data migration will allow predictive battery maintenance and increase the range of vehicles with the help of smart energy management systems.

2. Connected Vehicle Ecosystem

Moreover, connected cars result in the production of terabytes of sensor data per day, which need powerful cloud migration plans. Thus, car producers do not store data on a conventional platform but move to the scalable cloud services that deal with vehicle to everything (V2X) data.

Moreover, the integration of IoT sensors requires migration frameworks that can handle real-time telemetry of various systems on multiple vehicles at the same time.

3. Manufacturing Transformation

Likewise, Industry 4.0 projects push the process of moving automotive data to smart manufacturing systems. In the meantime, intelligent factory applications will demand the migration of the production data in order to have automated quality control and predictive maintenance of equipment.

4. AI-Powered Innovation

Autonomous Quality, Safety and Predictive Maintenance – Additionally, artificial intelligence applications require the transfer of historical data on vehicles in order to develop machine learning models to improve quality and increase safety.

Regulatory and Compliance Requirements – Lastly, changing automotive laws make it a complex process of migrating data to meet the requirements of safety regulations, emissions reporting, and cybersecurity issues.

The current automotive data movement plans have made it possible to take advantage of the power of advanced analytics among manufacturers without compromising regulatory compliance and operational efficiency during the digital transformation programs.

Common Automotive Data Migration Challenges

Data migration in the automotive industry has its own set of challenges, which need special strategies and skills. Organizations are also under serious challenges in migrating vital vehicle data, manufacturing information, and operational systems to the current digital infrastructure platforms.

1. Volume and Velocity Obstacles

To begin with, car manufacturers work with large volumes of data transmitted by connected cars, producing petabytes of sensor data every day. Migration tools should therefore be able to operate high velocity data streams without impacting performance of the system and its operations.

Additionally, car telemetry live generates continuous data ingestion problems that cannot be well addressed by the traditional migration methods.

2. Infrastructure Complexity

Moreover, the car manufacturers have complicated legacy systems that have developed over decades in technologic development. Hence, migration teams have proprietary protocols, old-fashioned database structures, and unmatched data formats, which make the process of transfers difficult.

Additionally, manufacturing systems that are crucial to the mission should have a thorough process of migration to avoid the disruption of production and the process of quality control.

3. Data Standardization and Quality Problems

Equally, automotive data is not always in a uniform format across various vehicle models, suppliers, and manufacturing stations. Meanwhile, the problem of data quality such as missing records and failure to calibrate sensors brings about complexities of validation in the migration.

To follow, standardization efforts demand a large amount of data cleaning and conversion prior to the successful migration accomplishment.

4. Processing Method Selection

In addition, the decision of real time migration and batch migration depends on the requirement of operation and the criticality of the system. Nonetheless, connected vehicle data requires real-time processing as compared to historical manufacturing data which is more appropriate to batch migration.

5. Security and Intellectual Property

Lastly, the protection of automotive intellectual property demands the implementation of high-security levels in the process of data migration. As a result, the companies will have to introduce encryption, access controls, and audit trails as a method of protecting proprietary vehicle design and manufacturing procedures.

To implement automotive data migration successfully, such challenges are to be mitigated by thorough planning and expertise in migration.

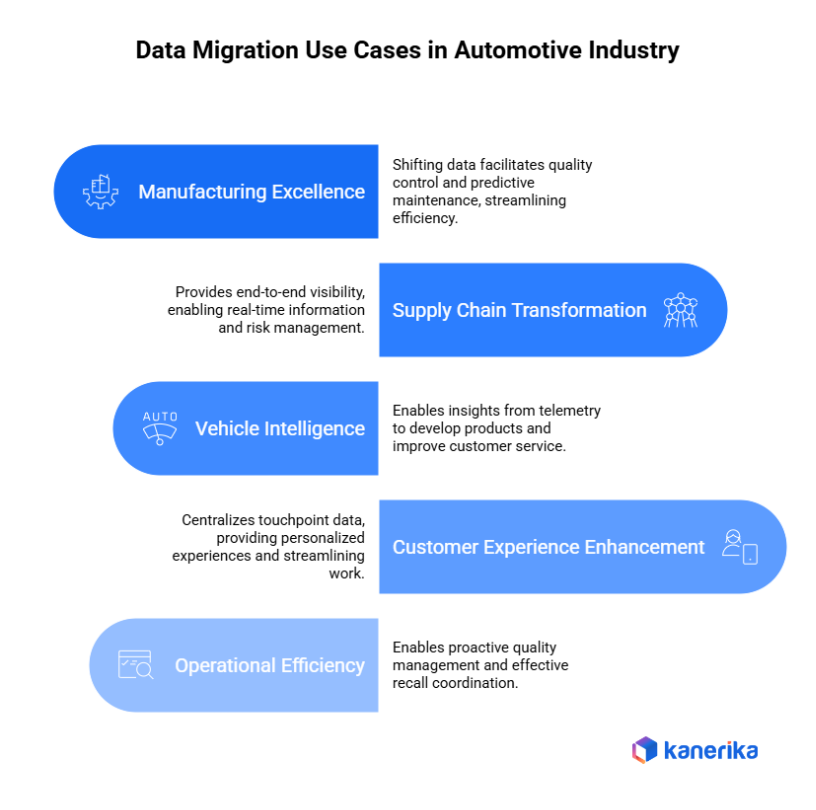

Data Migration Use Cases in Automotive Industry

Motor vehicle data migration facilitates transformational business performance in various business operations. Strategic data movement is used by organizations to unlock the superior analytics and enhance efficiency and customer satisfaction across automotive value chains.

1. Manufacturing Excellence

To start with, the automotive manufacturers shift the manufacturing data to facilitate the quality control in real-time and the equipment maintenance which is predictive. As a result, the current analytics systems interpret assembly line statistics, robotics performance information, and quality control metrics to streamline the manufacturing efficiency.

In addition, the transferred production data contributes to artificial intelligence (AI) can be used to detect defects and implement a quality control system, reducing the cost of production and enhancing the quality of the vehicles.

2. Supply Chain Transformation

Also supply chain information migration provides end-to-end visibility of intricate automotive vendor channels. As such, manufacturers are able to get real-time information about inventory, supplier performance, and logistics optimization opportunities.

Moreover, integrated supply chain analytics provides demand forecasting and risk management features that avert the breakdown of production and low inventory carrying costs.

3. Vehicle Intelligence

Likewise, automated vehicle data transfer makes car manufacturers able to use the insights of telemetry to develop products and improve customer service. In the meantime, the autonomous driving studies, predictive maintenance warnings, and customized driving experiences are supported by migrated vehicle sensor data.

Thereafter, real-time vehicle analytics enhances safety aspects as well as allowing new mobility services and revenue sources.

4. Customer Experience Enhancement

Also, the customer data migration centralizes the touchpoint data between dealerships, service centers, and digital channels. As a result, auto brands provide personalized experiences and streamline the work of dealers and customer satisfaction indicators.

5. Operational Efficiency

Lastly, proactive quality management and effective recall coordination is made possible through warranty data migration. Thus, manufacturers detect trends in the failure of components and simplify the procedure of warranty claims as well as the reporting of regulatory compliance.

The current automotive data migration plans change the capacities of operations and allow data-based innovation of the manufacturing, customer service, and product development projects that create competitive edge in the changing automotive markets.

Automotive Data Migration Architecture and Approaches

The automotive organizations need advanced data migration architectures to support intricate vehicle data ecosystems. The contemporary solutions need to strike a balance amid performance needs and scalability needs besides providing different automotive data types and real-time processing needs.

1. Migration Strategy Selection

Lift-and-Shift and Re-Platform and Re-Architect – To begin with, the automotive firms select three major migration strategies subject to both modernization objectives and technical needs. Lift-and-shift strategies therefore offer rapid automotive system migration to the cloud without substantial changes in the code.

In addition, re-platforming allows automotive manufacturers to modernize database technologies without altering any application logic. Nevertheless, re-architecting provides optimal gains through cloud-native automotive analytics system re-design.

Hence, automotive companies tend to mix solutions so that stable systems can be lifted and shifted and critical vehicle data platforms are re-architected.

2. Implementation of Cloud Strategy.

Hybrid and Multi-Cloud Strategy – Moreover, the automotive data migration is becoming more and more based on the hybrid cloud architecture, which preserves on-premise system of sensitive manufacturing data. In the meantime, multi-cloud strategies ensure vendor lock-in is avoided at the time when dependencies are being optimized between various automotive workloads.

Moreover, the hybrid solutions allow vehicle data processing in edge locations in real-time and retaining historical analytics in centralized clouds.

3. Data Processing Methodologies

Streaming and Batch Pipelines – On the same note, the process of data migration in automotive should involve a careful choice of either streaming or batch processing methods. Thereafter, the car telemetry requires real-time streaming pipelines to give real-time safety warnings and anticipatory maintenance signals.

Nonetheless, historical manufacturing data and warranty analytics can enjoy the effective mechanisms of batch processing optimizing the use of resources.

4. The architecture of modern Data platform

Purpose of Data Lakes and Lakehouses – Lastly, data migration in automotive is using more data lakehouse architectures that bring the flexibility of data lakes and the performance of data warehouses together. Therefore, these platforms permit both formal vehicle diagnostics and unstructured sensor data in cohesive automotive analytics settings.

Contemporary data migration strategies in the automotive industry combine these architectural models to develop scalability and performant platforms that not only address and fulfill the existing business requirements but also provide a framework upon which future automotive innovation projects can take place in the manufacturing industry and connected vehicle systems.

How to Migrate from SSRS to Power BI: Enterprise Migration Roadmap

Discover a structured approach to migrating from SSRS to Power BI, enhancing reporting, interactivity, and cloud scalability for enterprise analytics.

Automobile Data Migration Tools and Technologies

Migration of automotive data needs special tools and technologies that can manage various types of vehicle data and large volumes of processing requirements. Enterprises use end-to-end technology stacks to achieve a successful migration process as well as to sustain operations.

1. Data Integration Platforms

ETL/ELT Tools – The first is that automotive companies are using enterprise ETL solutions such as informatica power center and Talend to transform complex car data. Therefore, data about manufacturing, vehicle diagnostics, and supply chains are managed in such platforms using industry-oriented connectors.

Besides, new ELT techniques with the use of such tools as dbt allow the automotive organization to convert data in cloud platforms and enhance performance and scalability.

2. Cloud Infrastructure Solutions

Cloud Data Platforms – Moreover, car manufacturers switch to cloud computing services such as AWS, Microsoft Azure, and Google Cloud to provide scalable data processing services. Thus, these platforms provide support to significant amounts of vehicle telemetry and provide sophisticated analytics.

Moreover, car-optimized performance of automotive-oriented analytics and manufacturing intelligence is provided in cloud-native databases such as Snowflake and Databricks.

3. Real-Time Processing Technologies

Streaming Technologies – Equally, automotive data migration uses streaming databases such as Apache Kafka and AWS Kinesis to process real-time vehicle data. In the meantime, safety-critical vehicle alerts and predictive maintenance notifications can be immediately processed with the help of the technologies.

In turn, autonomous vehicle data requirements and connected car ecosystems are practically supported with the help of streaming architectures.

4. Quality Assurance and Validation

Data Quality and Reconciliation Tools – Besides, automotive migrations need special reconciliation software such as QuerySurge and Informatica Data Validation so that vehicle data could be accurate. Nonetheless, vehicle-specific validation standards deal with the industry-specific needs such as sensor calibration and safety standards.

Migration Accelerators – Lastly, migrators and automation systems used by automotive organizations minimize the project schedule and minimize risks. As such, the tools facilitate the process of complex automotive data migration and also promote regulatory compliance and operational continuity.

Current automotive data migration is a combination of these technologies that provide strong and scalable platforms that contribute to present day automotive operations and further automotive innovation programs.

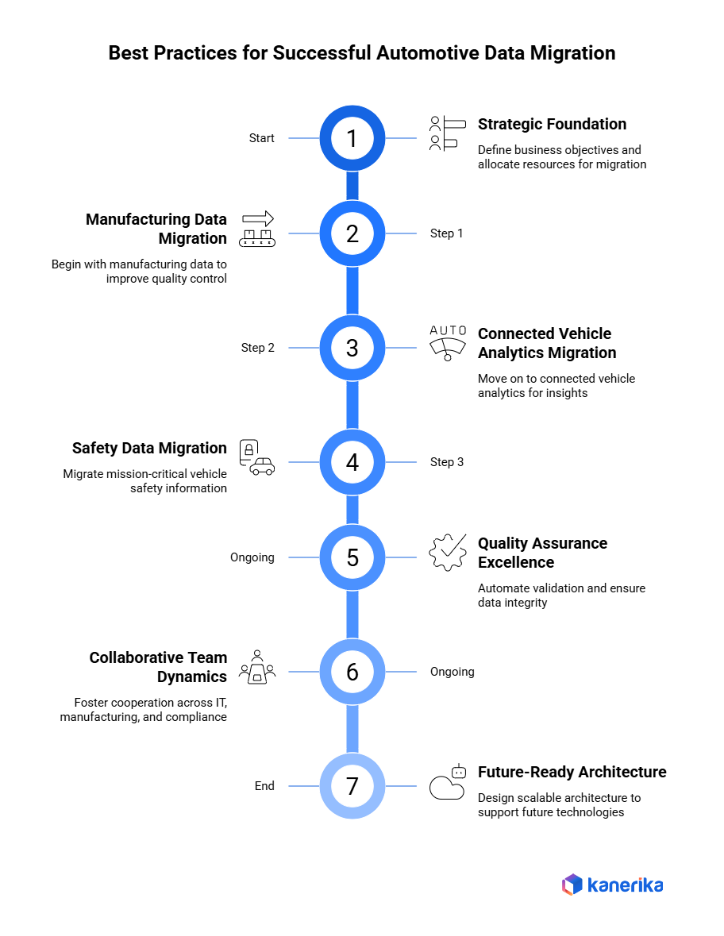

Best Practices for Successful Automotive Data Migration

The success in the migration of automotive data demands planning and industry-related knowledge to work with complex vehicle ecosystems. Companies should adopt best practices that will solve distinctive automotive problems and provide quantifiable business benefits.

1. Strategic Foundation

To start with, automotive data migration is a process that requires well-instilled business objectives in accordance with the digital transformation goals. Organizations are therefore supposed to come up with certain results such as an increase in manufacturing efficiency, enhancement of vehicle analytics, or customer experience metrics.

In addition, resource allocation is part of business-driven migration strategies to guarantee the provision of resources in line with priorities in automotive such as safety compliance, quality enhancement, and operational excellence.

2. Structured Implementation Approach

Also, the automotive firms enjoy domain-based migration stages which reduce operational risks. Thus, companies must focus on the areas of migration in the order of importance of the business but begin with manufacturing data and then move on to connected vehicle analytics.

Thereafter, gradual strategies enable the automotive groups to test migration steps and improve the methodologies until they can deal with mission-critical vehicle safety information.

3. Quality Assurance Excellence

On the same note, automated validation tools maintain automotive data integrity during the migration processes. Concurrently, automation of reconciliation minimizes errors during the manual process and shortens the time-span of validation on complicated sets of vehicles.

In addition, automotive specific validation laws are used to accommodate the industry demands such as sensor calibration accuracy and verification of regulatory compliance.

4. Collaborative Team Dynamics

Furthermore, it is important to mention that automotive migration is only possible when IT, manufacturing, engineering, and compliance teams cooperate. Nonetheless, cross-functional involvement would guarantee that migration strategies focus on the needs of various stakeholders and sustainability of operations.

5. Future-Ready Architecture

Lastly, the automotive data migration architecture should be able to support future connected vehicle expansion and the new technologies such as autonomous driving systems.

Thereby, scalable migration plans make the automotive organizations ready to further innovate, as well as enable the organizations to meet the future industry demands and regulatory demands in the international automotive markets.

Case Study 1: Transforming Enterprise Data with Automated Migration from Informatica to Talend

Client Challenge

The client used a large Informatica setup that became costly and slow to manage. Licensing fees kept rising. Workflows were complex, and updates needed heavy manual work. Modernization stalled because migrations took too long.

Kanerika’s Solution

Kanerika used FLIP to automate the conversion of Informatica mappings and logic into Talend. FIRE extracted repository metadata so the team could generate Talend jobs with minimal manual rework. Outputs were validated through controlled test runs and prepared for a cloud-ready environment.

Impact Delivered

• 70% reduction in manual migration effort

• 60% faster time to delivery

• 45% lower migration cost

• Better stability through accurate logic preservation and smooth cutover

Case Study 2: Migrating Data Pipelines from SSIS to Microsoft Fabric

Client Challenge

The client’s SSIS-based pipelines were slow, expensive, and hard to maintain. Reports refreshed slowly, and the platform needed too much manual intervention.

Kanerika’s Solution

Kanerika rebuilt the client’s pipelines using PySpark and Power Query inside Microsoft Fabric. SSIS logic was mapped to the right Fabric components and transformed into Dataflows and PySpark notebooks. A unified Lakehouse structure improved performance and simplified monitoring.

Impact Delivered

• 30% faster data processing

• 40% reduction in operational cost

• 25% less manual maintenance

• Improved scalability through a modern Fabric-based architecture

Kanerika Enables Seamless Automotive Data Migration with Automation and AI

Kanerika helps automotive Tier-1 suppliers, and mobility organizations modernize their data architecture and analytics through fast, secure, and intelligent automotive data migration strategies. Traditional automotive systems often struggle with high-volume manufacturing data, fragmented ERP, MES, PLM, and dealer platforms, and the growing demand for real-time vehicle and production insights.

As automotive operations expand across plants, regions, and partner ecosystems, these challenges limit visibility, slow decision-making, and reduce operational efficiency. Therefore, modernizing data platforms has become a critical priority for the industry.

Kanerika’s approach ensures a smooth migration from legacy automotive systems to modern, cloud-native platforms, while minimizing disruption to ongoing manufacturing, supply chain, dealer, and connected-vehicle operations.

Our End-to-End Automotive Data Migration Services

Kanerika delivers comprehensive migration services across key automotive data domains:

1. BI Migration

Replacement of previous reporting systems like Tableau, Cognos, SSRS and crystal reports with Power BI to utilize real-time dashboards to monitor the performance of the production process, quality indicators, warranty analysis and sales data.

2. Data Warehouse to Data Lake Migration

Transition from rigid, on-premise data warehouses to flexible data lake or lakehouse platforms that can handle structured, semi-structured, and unstructured automotive data, including sensor data, vehicle logs, and manufacturing events.

3. Cloud Migration

Move automotive workloads to secure and scalable cloud platforms such as Azure or AWS to improve performance, resilience, and cost efficiency across manufacturing, engineering, and analytics operations.

4. ETL and Pipeline Migration

Modernize data pipelines to support faster ingestion, transformation, and orchestration of automotive data from ERP, MES, PLM, dealer systems, and connected vehicle platforms.

5. RPA Platform Migration

Upgrade automation workflows from UiPath to Microsoft Power Automate to streamline automotive processes such as order management, production reporting, reconciliation, and exception handling.

Powered by FLIP: Smart Migration Accelerators

Kanerika’s proprietary FLIP platform accelerates automotive data migration using Smart Migration Accelerators. FLIP automates up to 80% of the migration process, significantly reducing manual effort while preserving business logic, data quality, and historical accuracy.

It supports complex automotive transitions such as Tableau to Power BI, SSIS to Microsoft Fabric, and Informatica to Talend, while ensuring zero data loss and minimal impact on production and engineering workflows.

Secure, Compliant, and Future-Ready Automotive Data Platforms

Throughout the migration journey, Kanerika ensures strict adherence to global security and compliance standards, including ISO 27001, ISO 27701, SOC 2, and GDPR. This governance-first approach is especially critical for automotive organizations managing sensitive IP, manufacturing data, and customer information.

By combining deep expertise in automation, AI, cloud engineering, and data governance, Kanerika enables automotive enterprises to unlock predictive insights, improve operational efficiency, and build a scalable, future-ready data foundation. As a result, organizations gain real-time visibility, faster innovation cycles, and data-driven decision-making that supports long-term growth.

Frequently Asked Questions

1. What is data migration in the automotive industry?

Data migration in the automotive industry is the process of moving data from legacy systems to modern platforms such as cloud, data lakes, or lakehouses. This includes data from ERP, MES, PLM, connected vehicles, dealer systems, and manufacturing plants. The goal is to improve data accessibility, scalability, and analytics readiness. It forms the foundation for automotive digital transformation.

2. Why is data migration critical for automotive enterprises today?

Automotive companies are shifting toward electric, connected, and software-defined vehicles. These changes generate massive volumes of data that legacy systems cannot handle efficiently. Data migration enables real-time insights, advanced analytics, and faster decision-making. Without migration, innovation and operational efficiency are limited.

3. What types of automotive data are typically migrated?

Automotive data includes structured data like production records, sales transactions, and warranty claims, as well as unstructured data such as sensor data, vehicle logs, images, and telematics. Both types must be migrated and integrated for complete visibility. A unified data platform enables better analytics and AI use cases.

4. What are the biggest challenges in automotive data migration?

Common challenges include high data volumes, complex legacy systems, inconsistent data standards, and strict security requirements. Real-time data from connected vehicles adds further complexity. Without proper planning and governance, migrations can result in data loss or performance issues. Automation and validation are key to overcoming these challenges.

5. How does cloud migration support automotive data modernization?

Cloud platforms provide scalability, flexibility, and performance needed for modern automotive workloads. Migrating data to cloud environments supports real-time analytics, predictive maintenance, and AI-driven insights. It also reduces infrastructure costs and improves resilience. This makes cloud migration a core part of automotive data strategies.

6. How can automotive organizations ensure secure and compliant data migration?

Security and compliance require encryption, access controls, and audit trails throughout the migration process. Automotive companies must protect intellectual property, manufacturing data, and customer information. Governance frameworks and automated validation help meet regulations like GDPR and industry standards. Security must be built into every migration phase.

7. What long-term value does data migration deliver to automotive businesses?

Beyond modernization, data migration enables predictive analytics, improved quality control, and enhanced customer experiences. It supports innovation in areas like EVs, connected vehicles, and smart manufacturing. A future-ready data foundation helps automotive enterprises stay competitive in a rapidly evolving market.