Companies aggressively digitizing their supply chains can boost annual earnings growth by 3.2%, the largest increase from digitizing any business area, according to Mckinsey research. That’s a clear return but getting there requires choosing the right supply chain analytics tools.

Most supply chain managers face the same problem. You have data scattered across different systems but turning it into useful insights takes too long. By the time you spot a problem, it’s already costing you money.

Supply chain analytics tools solve this. They pull data from your warehouse systems, transportation networks, and inventory databases into one place. You get clear answers about where delays happen, which suppliers perform best, and how to reduce costs.

But picking the right tool isn’t straightforward. Some are built for large manufacturers. Others work better for retailers or distributors. Price tags range from a few thousand to millions per year.

This guide walks through everything you need to know. We’ll cover what these tools actually do, which features matter most, and how to match a solution to your specific needs. You’ll also see detailed comparisons of the leading platforms and practical steps for implementation.

Key Takeaways

- Supply chain analytics tools consolidate data from ERP, warehouse, and transportation systems into one platform, turning scattered information into actionable insights that help cut costs and reduce delays

- Companies using AI-enabled supply chain analytics report 15% reductions in logistics costs and achieve better inventory management while improving service delivery and customer satisfaction

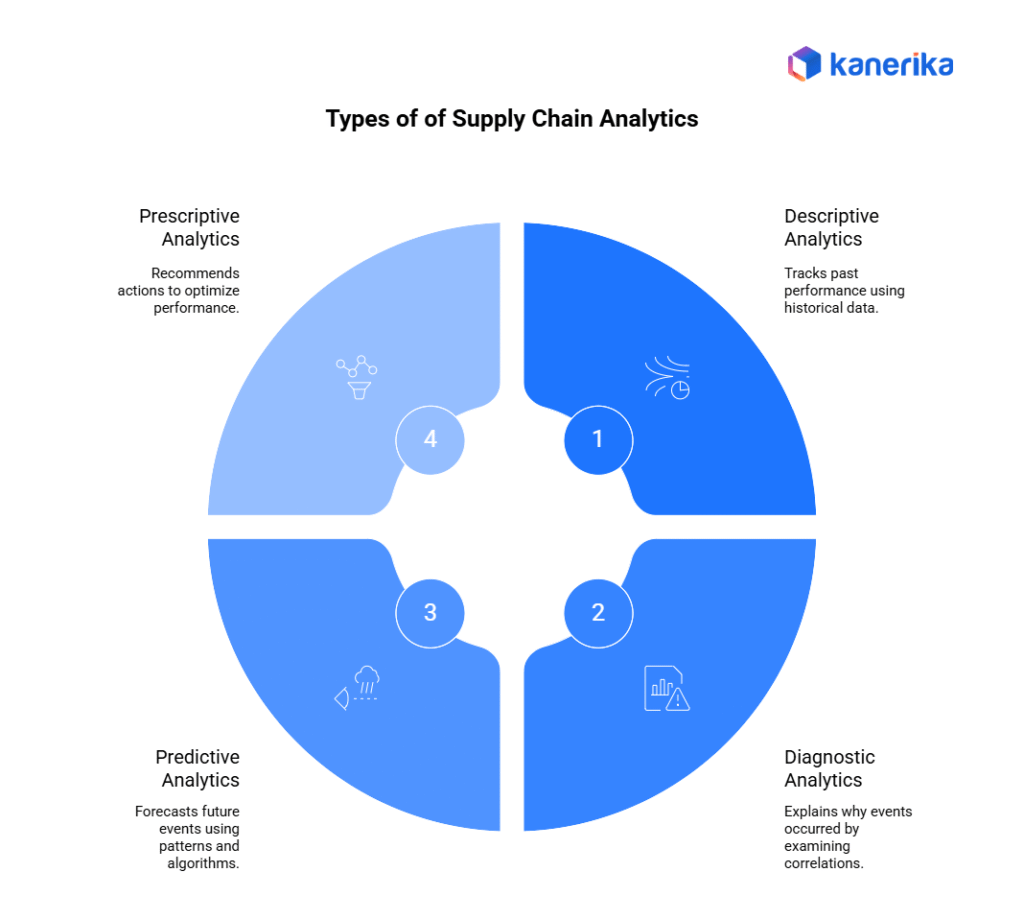

- Four types of analytics serve different purposes: descriptive tracks what happened, diagnostic explains why, predictive forecasts future demand, and prescriptive recommends specific optimization actions

- Essential features include data integration capabilities, AI and machine learning for forecasting, real-time visualization dashboards, collaboration tools, and scalability to handle growing business complexity

- Top platforms like Microsoft Fabric, Databricks, SAP IBP, and Kinaxis offer different strengths with pricing ranging from $263 monthly for basic tools to custom enterprise quotes for comprehensive solutions

Elevate Your Enterprise Data Operations with Expert Analytics Services!

Partner with Kanerika Today!

What Are Supply Chain Analytics?

Supply chain analytics is the process of collecting and analyzing data from your procurement, manufacturing, warehousing, and distribution operations. These tools connect information from different systems like your ERP, warehouse management software, and transportation platforms. The goal is simple: turn raw data into actionable insights that help you cut costs, reduce delays, improve inventory accuracy, and make faster decisions across your entire supply network.

Types of Supply Chain Analytics

1. Descriptive Analytics

This tells you what happened in your supply chain. It tracks past performance through reports and dashboards showing metrics like order volumes, delivery times, and inventory levels. Most companies start here because it uses historical data you already have.

2. Diagnostic Analytics

This explains why something happened. When you see a spike in transportation costs or a drop in on-time deliveries, diagnostic analytics digs into the root causes. It examines correlations between different variables to pinpoint exactly where problems originate.

3. Predictive Analytics

This forecasts what will happen next. Using historical patterns and machine learning algorithms, predictive tools estimate future demand, identify potential supply disruptions, and anticipate inventory shortages. Companies use this for demand forecasting and risk management planning.

4. Prescriptive Analytics

This recommends what you should do. The most advanced type, prescriptive analytics suggests specific actions to optimize your supply chain performance. It runs scenario simulations and provides data-driven recommendations for route optimization, supplier selection, and inventory allocation decisions.

Predictive Analytics in Retail: 10 Real-World Use Cases You Need to know

Discover 10 real-world use cases of predictive analytics in retail to enhance customer experience.

What Are Supply Chain Analytics Tools?

Supply chain analytics tools are software platforms that help businesses track, measure, and improve their supply chain operations. They collect data from multiple sources to give you insights into inventory levels, shipping times, supplier performance, and demand patterns. Examples include Kinaxis, Blue Yonder, SAP Integrated Business Planning, and Llamasoft.

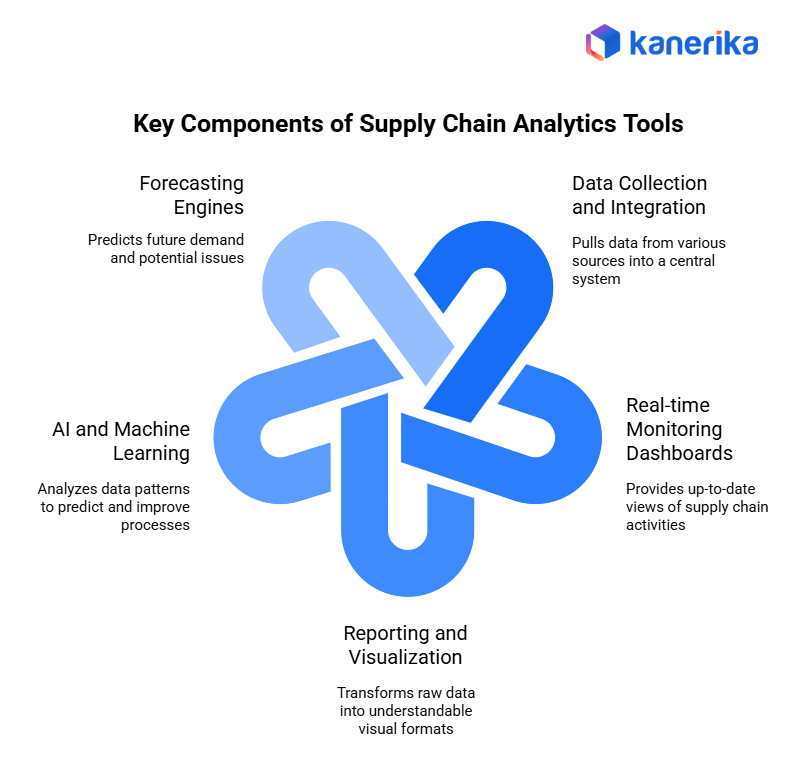

What are the Key Components of Supply Chain Analytics Tools?

1. Data Collection and Integration Capabilities

These tools pull data from various sources across your supply chain. Think ERP systems, warehouse management software, transportation platforms, and supplier databases. Everything feeds into one central system.

The integration part matters because most companies use different software for different operations. Good analytics tools connect all these systems so your data actually works together instead of sitting in silos.

2. Real-time Monitoring Dashboards

Dashboards show what’s happening in your supply chain right now. You can see inventory levels, shipment statuses, production rates, and potential delays. Everything updates automatically as new data comes in.

The real-time aspect helps you spot problems early. If a shipment gets delayed or inventory drops too low, you’ll know immediately instead of finding out days later when it’s harder to fix.

3. Reporting and Visualization Features

These features turn raw data into charts, graphs, and reports that actually make sense. Instead of looking at spreadsheets full of numbers, you get visual representations that show trends and patterns clearly.

Most tools let you customize reports for different people. Operations teams might need detailed logistics reports while executives want high-level summaries. The same data gets presented in different ways depending on who needs it.

4. AI and Machine learning capabilities

AI analyzes patterns in your supply chain data to find insights humans might miss. It can identify inefficiencies, predict disruptions, and suggest improvements based on what it learns from your historical data.

Machine learning gets smarter over time. The more data it processes, the better it becomes at spotting anomalies and making accurate predictions. This helps automate decisions that used to require manual analysis.

5. Forecasting engines

Forecasting engines predict future demand, inventory needs, and potential supply chain issues. They use historical data, market trends, and seasonal patterns to estimate what’s coming next.

Better forecasts mean you can prepare instead of react. You’ll know when to order more inventory, adjust production schedules, or find backup suppliers before problems actually hit your operations.

Top 10 Business Intelligence Tools: Features, Benefits & How to Choose

Explore top business intelligence tools, their features, and benefits for smarter decision-making.

Use Cases of Supply Chain Analytics Tools Across Industries

1. Manufacturing

Production planning gets more accurate when you can track materials, equipment, and labor in real time. Supply chain analytics software helps manufacturers reduce downtime and meet delivery schedules without overproducing.

59% of manufacturing companies now use predictive analytics to anticipate demand shifts and manage supply chain risks. The tools process data from your production floor, supplier networks, and logistics partners to spot bottlenecks before they impact output.

- Demand forecasting lets you adjust production volumes based on market signals instead of gut feelings

- Inventory optimization cuts carrying costs by showing exactly when to reorder parts and raw materials

- Quality control tracking identifies patterns in defects across batches, suppliers, or production lines

2. Retail and E-commerce

Your customers expect products to be in stock and delivered fast. Supply chain management tools track inventory across warehouses, stores, and fulfilment centers so you never lose a sale to stockouts.

Retail supply chain analytics turn purchase history and browsing data into actionable forecasts. You can predict which products will sell where and when, then position inventory accordingly.

- Omnichannel inventory visibility shows real-time stock levels across all sales channels

- Last-mile delivery optimization reduces shipping costs while meeting delivery promises

- Returns management analyzes return patterns to reduce losses and improve product selection

3. Healthcare and Pharmaceuticals

Temperature-sensitive medications and strict compliance requirements make healthcare supply chains complex. Analytics platforms track products from manufacturing through patient delivery while maintaining regulatory documentation.

Pharmaceutical companies have achieved 20% reductions in inventory holding costs Cost Savings in Pharma Through AI Optimization by using AI-powered demand forecasting. The technology helps maintain adequate stock levels without excess inventory that might expire.

- Cold chain monitoring alerts you immediately if temperature-controlled products are compromised

- Expiry date management prevents waste by prioritizing products nearing expiration

- Regulatory compliance tracking maintains complete chain of custody records for audits

4. Food and Beverage

Perishable goods require precise supply chain orchestration. Analytics tools monitor shelf life, storage conditions, and demand patterns to minimize spoilage while ensuring product availability.

Food supply chain software connects data from farms, processing facilities, distributors, and retailers. You get visibility into freshness, quality issues, and recall tracking across the entire supply network.

- Freshness tracking monitors product age and recommends distribution routes that maximize shelf life

- Supplier quality scoring evaluates vendors based on delivery consistency and product quality

- Seasonal demand planning adjusts production and inventory for predictable consumption patterns

5. Automotive

Just-in-time manufacturing requires synchronized delivery of thousands of parts from global suppliers. Supply chain analytics platforms coordinate complex supplier networks to prevent production line stoppages.

Automotive manufacturers use these tools to manage tier-one, tier-two, and tier-three suppliers simultaneously. The software tracks part availability, shipping status, and potential disruptions across multiple continents.

- Supplier risk assessment identifies vulnerable points in your supply base before disruptions occur

- Parts synchronization ensures all components arrive at assembly plants exactly when needed

- Warranty claims analysis links product defects back to specific suppliers or production batches

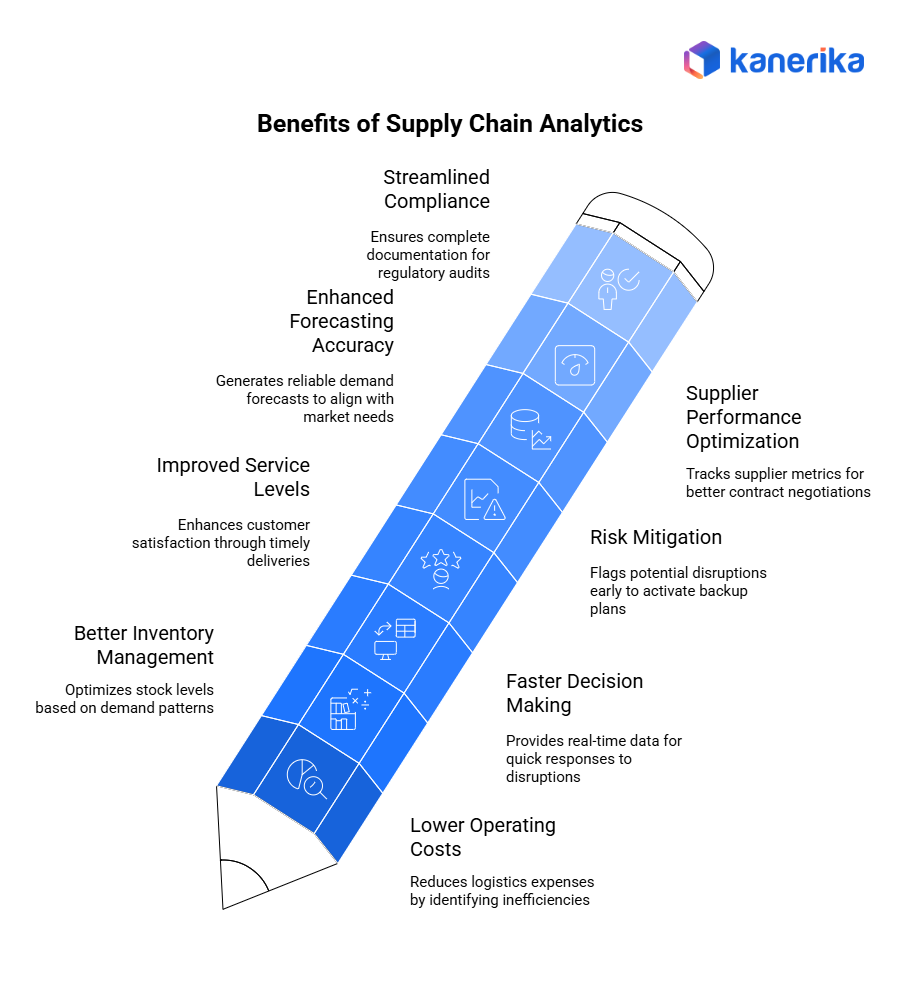

What Are the Business Benefits of Using Supply Chain Analytics Tools?

1. Lower Operating Costs

Companies using AI-enabled supply chain analytics report 15% reductions in logistics costs. The software identifies inefficiencies in transportation routes, warehouse operations, and procurement spending. You stop wasting money on expedited shipping, excess inventory, or underutilized assets.

2. Better Inventory Management

Organizations adopting advanced analytics & agentic AI in supply chain see inventory levels drop significantly without compromising product availability. The tools calculate optimal stock levels based on actual demand patterns rather than guesswork. Your capital isn’t tied up in products sitting in warehouses.

3. Faster Decision Making

Real-time dashboards give you immediate access to supply chain performance data. You can respond to disruptions, demand spikes, or quality issues within hours instead of days. Leadership teams make informed choices backed by current information rather than outdated reports.

4. Improved Service Levels

Service efficiency improves drastically with AI-powered supply chain management Customers get their orders on time because you can predict delays and adjust proactively. Better fulfillment rates translate directly into higher customer retention and satisfaction scores.

5. Risk Mitigation

Supply chain analytics platforms flag potential disruptions before they impact operations. You get early warnings about supplier financial trouble, geopolitical issues, or weather events affecting shipments. This visibility lets you activate backup plans instead of scrambling during a crisis.

6. Enhanced Forecasting Accuracy

Predictive analytics tools process historical data, market trends, and external factors to generate reliable demand forecasts. Your production schedules align with actual market needs. You avoid both stockouts that lose sales and overproduction that creates waste.

7. Supplier Performance Optimization

The software tracks delivery times, quality metrics, and pricing from every vendor in your network. You identify which suppliers consistently meet standards and which ones create problems. Contract negotiations become easier when you have objective performance data.

8. Streamlined Compliance

Automated tracking ensures you maintain complete documentation for regulatory audits. The system records every transaction, movement, and quality check across your supply chain. When regulators or customers ask for proof, you can produce accurate records instantly.

Why AI and Data Analytics Are Critical to Staying Competitive

AI and data analytics empower businesses to make informed decisions, optimize operations, and anticipate market trends, ensuring they maintain a strong competitive edge.

Top 10 Supply Chain Analytics Tools

1. Microsoft Fabric

Microsoft Fabric combines data integration, engineering, and business intelligence into a unified analytics platform. Built on Azure infrastructure, it helps supply chain teams consolidate data from multiple sources and apply AI-powered insights to optimize operations.

Key Features

- Real-time data streaming for inventory and shipment tracking

- OneLake unified data lake for centralized supply chain data storage

- Power BI integration for interactive dashboards and reports

- AI-powered forecasting with Copilot capabilities

Pricing Capacity-based pricing starting at $262.80/month for F2 capacity. Storage costs approximately $0.023 per GB/month. 60-day free trial available.

2. Databricks

Databricks delivers a lakehouse platform that processes massive supply chain datasets using Apache Spark. The platform excels at building machine learning models for demand forecasting, route optimization, and predictive maintenance across global supply networks.

Key Features

- Delta Lake architecture for reliable data processing at scale

- MLflow for managing supply chain prediction models

- Real-time stream processing for logistics tracking

- Collaborative notebooks for cross-functional supply chain teams

Pricing Pay-as-you-go model with per-second billing. Pricing varies by cloud provider (AWS, Azure, GCP) and workload type. No upfront costs or contracts required.

3. SAP Integrated Business Planning (IBP)

SAP IBP provides end-to-end supply chain planning from demand sensing to inventory optimization. The cloud-based platform integrates with SAP ERP systems and uses statistical algorithms plus machine learning for accurate forecasts.

Key Features

- Sales and operations planning with scenario modeling

- Demand sensing that responds to market changes within days

- Inventory optimization across multi-echelon networks

- Supply chain control tower for real-time visibility

Pricing Custom pricing based on users, modules, and transaction volumes. Contact SAP for enterprise quotes.

4. Kinaxis RapidResponse

Kinaxis specializes in concurrent planning where all supply chain functions work from a single data model. The platform updates plans continuously as conditions change, letting you respond to disruptions within minutes.

Key Features

- What-if scenario analysis for risk assessment

- Concurrent planning that eliminates data silos

- Supply chain control tower with alerts

- Master data management for supplier networks

Pricing Custom enterprise pricing based on planning complexity and user count. Quote-based model.

5. Blue Yonder (formerly JDA)

Blue Yonder combines supply chain planning, warehouse management, and transportation optimization in one platform. The system uses AI to automate replenishment decisions and optimize fulfillment across omnichannel retail operations.

Key Features

- Luminate AI platform for autonomous supply chain decisions

- Warehouse management with robotics integration

- Transportation management and route optimization

- Demand forecasting with external data signals

Pricing Custom pricing based on modules selected and company size. Enterprise quote required.

6. Oracle Supply Chain Management Cloud

Oracle SCM Cloud covers procurement, manufacturing, order management, and logistics in an integrated suite. The platform connects with Oracle ERP and uses blockchain for supply chain traceability.

Key Features

- IoT integration for real-time asset tracking

- Blockchain network for supplier verification

- Predictive maintenance for manufacturing equipment

- Supply chain financial planning integration

Pricing Subscription pricing starts at approximately $175/user/month for core SCM modules. Contact Oracle for bundled pricing.

7. Anaplan

Anaplan provides connected planning that links supply chain operations to financial planning. The platform’s in-memory calculation engine handles complex planning scenarios across sales, operations, and finance teams.

Key Features

- Connected planning across functions

- Flexible modeling for custom supply chain workflows

- Scenario planning with version control

- Mobile access for field operations teams

Pricing Custom pricing based on users and data volume. Enterprise licenses typically start around $30,000 annually.

8. o9 Solutions

o9 delivers an AI-powered platform that unifies planning across demand, supply, and integrated business planning. The Digital Brain technology processes external signals like weather, social media, and economic indicators for better forecasts.

Key Features

- Digital Brain AI for multi-factor demand sensing

- Integrated business planning from strategy to execution

- Sustainability analytics for carbon footprint tracking

- Graph technology for supplier network analysis

Pricing Custom enterprise pricing. Quote-based on planning scope and user requirements.

9. Infor Nexus

Infor Nexus operates a multi-enterprise supply chain network connecting buyers, suppliers, and logistics providers. The platform provides visibility across partner networks with embedded collaboration tools.

Key Features

- Multi-enterprise network with 75,000+ connected companies

- Purchase order management with supplier portals

- Logistics visibility across carriers

- Trade compliance management for global shipping

Pricing Network-based pricing model with transaction fees. Contact Infor for specific pricing tiers.

10. Llamasoft (Coupa Supply Chain Design & Analysis)

Llamasoft focuses on supply chain network design and optimization. The platform models your entire supply chain to identify cost savings opportunities and evaluate network changes before implementation.

Key Features

- Network design optimization for facilities and routes

- Digital twin modeling for scenario testing

- Carbon footprint analysis for sustainability goals

- Risk assessment for supplier dependencies

Pricing: Custom pricing based on network complexity and modules. Enterprise quotes available through Coupa.

Microsoft Fabric vs Power BI: A Comparative Analysis

Explore how to select the best data visualization tool to enhance insights, streamline analysis, and effectively communicate data-driven stories.

Outsmart Your Competition with Kanerika Innovative Analytics Solutions

Kanerika is a premier Data and AI solutions company helping businesses make sense of their data with speed and accuracy. Our advanced data analytics solutions are built to uncover insights hidden within large and complex data estates, enabling faster and more informed decision-making.

As a certified Microsoft and Databricks partner, we combine the strength of Microsoft Fabric, Power BI, and the Databricks Data Intelligence Platform to deliver analytics that truly work for your business.

Our experts design solutions that don’t just solve data challenges but improve how your entire data ecosystem operates. From building scalable data pipelines to creating real-time dashboards, our focus is on clarity, precision, and measurable business value.

With Kanerika, you get more than analytics — you gain a partner who helps transform your data into a driver of growth and innovation.

Optimize Your Data Strategy with Advanced Data Analytics Solutions!

Partner with Kanerika Today.

Frequently Answered Questions

What are supply chain analytics tools?

Supply chain analytics tools are software platforms that collect and analyze data from your procurement, warehousing, and distribution operations. They connect information from different systems like ERP, warehouse management, and transportation platforms. The goal is to turn raw data into insights that help you cut costs, reduce delays, and make faster decisions across your supply network.

How do supply chain analytics tools improve efficiency?

These tools identify inefficiencies in your operations by analyzing data patterns. They show you where delays happen, which routes cost too much, and where inventory sits too long. Companies using AI-enabled supply chain analytics report 15% reductions in logistics costs. You get real-time visibility that helps you fix problems before they escalate into expensive disruptions.

What's the difference between descriptive and predictive analytics in supply chains?

Descriptive analytics tells you what already happened by tracking past performance like delivery times and order volumes. Predictive analytics forecasts what will happen next using historical patterns and machine learning. It estimates future demand, identifies potential disruptions, and anticipates inventory shortages. Most companies start with descriptive analytics, then add predictive capabilities as they mature.

Which industries benefit most from supply chain analytics tools?

Manufacturing, retail, healthcare, food and beverage, and automotive industries see significant benefits. Manufacturers use them for production planning and quality control. Retailers optimize inventory across multiple channels. Healthcare companies track temperature-sensitive medications and maintain compliance. Food businesses monitor freshness and reduce spoilage. Any industry with complex logistics can benefit from better data visibility.

How much do supply chain analytics tools cost?

Pricing varies widely based on company size and features needed. Some tools like Microsoft Fabric start around $263 monthly. Enterprise platforms like SAP IBP or Kinaxis require custom quotes that can reach hundreds of thousands annually. Consider implementation costs, training, and integration work. Many vendors offer pay-as-you-go models or free trials before committing.

Can small businesses use supply chain analytics tools?

Yes. Cloud-based tools with flexible pricing make analytics accessible to smaller companies. You don’t need massive IT infrastructure anymore. Start with basic features like inventory tracking and reporting, then add capabilities as you grow. Look for platforms with modular pricing so you only pay for what you actually use right now.

How long does it take to implement supply chain analytics software?

Implementation time depends on your data complexity and existing systems. Basic setups can go live in weeks. Enterprise deployments with custom integrations across multiple locations may take several months. Data migration and cleaning often takes longer than expected. Factor in training time for your team to actually use the system effectively.

What data sources do supply chain analytics tools integrate with?

These platforms connect with ERP systems, warehouse management software, transportation platforms, supplier databases, and IoT sensors. They pull data from systems like SAP, Oracle, Microsoft Dynamics, and shipping carriers. Good tools use APIs for automatic data sync. The best platforms offer pre-built connectors for common systems to speed up integration.