Mercedes debuted an enhanced MBUX Virtual Assistant in the new CLA class cars, powered by Google’s Automotive AI Agent. It combines natural voice interaction with real-time data, showcasing the role of data analytics in the automotive industry to create a more intuitive driving experience.

Additionally, McKinsey predicts that advanced driver-assistance systems (ADAS) and autonomous driving could generate up to $400 billion in annual revenue by 2035, showing how fast the industry is moving toward intelligent, connected vehicles.

From virtual assistants to generative design, data analytics in the automotive industry is enabling companies to blend innovation with comfort and safety.

Stay Ahead with Data Analytics in the Automotive Industry.

Partner with Kanerika to implement AI-driven solutions for smarter operations.

What Is Data Analytics in the Automotive Industry?

Data analytics in the automotive industry refers to the process of collecting, processing, and interpreting data from different sources across the automotive ecosystem. This includes design, production, supply chain, dealerships, and customer interactions.

Instead of relying solely on manual reports or past performance, automotive companies now use predictive models and machine learning algorithms to make faster and smarter decisions. For example:

- Engineers can identify design flaws early, before mass production.

- Manufacturers can track and eliminate bottlenecks in real time.

- Dealers can personalize offers to customers based on driving behavior.

Therefore, companies that invest in data analytics in the automotive industry are staying ahead of the curve.

Types of Data Collected

Automotive companies handle massive volumes of structured and unstructured data every day. Some of the most common sources include:

- Manufacturing processes – production line sensors, defect tracking, and equipment performance data.

- Supply chain flows – logistics data, demand forecasts, supplier performance metrics.

- Vehicle sensors & telematics – GPS, OBD (on-board diagnostics), LiDAR, and cameras generating real-time insights.

- Customer interactions – dealership visits, service history, CRM systems, loyalty programs.

- Connected car feedback – infotainment usage, driver behavior, in-car preferences.

Together, these data streams create a 360-degree view of vehicles and customers, enabling decision-makers to act with precision.

Why Analytics is a Competitive Advantage

Companies that invest in analytics enjoy a clear advantage over traditional players. Benefits include:

- Speed – real-time insights help automakers detect problems immediately.

- Accuracy – machine learning reduces human error in defect detection or forecasting.

- Cost control – predictive analytics minimizes recalls, downtime, and excess inventory.

For instance, a manufacturer using AI-driven visual inspections can identify defects at scale—cutting rework costs and ensuring higher product reliability. In contrast, companies that still depend on manual checks risk slower production and higher recall costs.

Data Analytics Trends in 2025: What You Need to Know

Learn the key data analytics trends for 2025, including AI, real-time insights, and stronger data security.

Applications of Data Analytics in the Automotive Industry

1. Manufacturing Optimization

Automotive manufacturers rely on data analytics to improve quality control and reduce production errors. AI systems now scan components in real-time, flagging defects before they reach the assembly stage. This reduces waste, speeds up production, and improves consistency across plants. In parallel, some teams also conduct automotive pentesting to ensure that connected systems remain secure throughout the production process.

For example, Ford has implemented two AI-based systems—AiTriz and MAIVS—across hundreds of assembly stations in North America. These tools detect tiny misalignments and surface flaws before vehicles leave the factory, cutting rework and warranty costs.

Similarly, BMW’s “drive-through MRI for cars” in Honolulu uses a 360° AI scan to detect damage instantly, cutting inspection times in half while boosting accuracy. These cases show how analytics-driven inspection is setting new benchmarks in precision and efficiency.

2. Supply Chain and Inventory Management

Analytics makes supply chains leaner and more responsive. By syncing production with actual demand, companies reduce excess inventory, shorten lead times, and lower holding costs. Forecasting tools also help predict supplier risks and adjust procurement strategies.

Toyota’s Just-In-Time (JIT) system is a classic yet evolving example. By integrating data analytics with its lean philosophy, Toyota reduced excess stock, improved turnover cycles, and cut holding costs by nearly 40%. Even during the 1997 Aisin factory fire, Toyota’s analytics-backed supplier collaboration helped restore production in just five days, displaying how data-driven agility safeguards continuity in high-stakes scenarios.

4. Predictive Maintenance and Vehicle Health Monitoring

Predictive maintenance uses sensor data and machine learning to spot issues before they cause breakdowns. This reduces unplanned downtime, lowers repair costs, and extends vehicle life. It also helps manufacturers keep production lines running smoothly.

In 2025, Tesla and BMW showcased this advantage with AI-driven predictive maintenance. Tesla cut factory downtime by over 30%, while BMW reduced assembly disruptions by 500 minutes annually. On the consumer side, Tesla’s Battery Health Test (delivered via an over-the-air update) allows owners to monitor battery efficiency without visiting a service center, improving customer trust while lowering maintenance overhead.

5. Customer Experience and Personalization

Analytics helps automakers personalize services based on user behavior. By combining CRM data with connected car insights, companies can offer tailored maintenance and driving tips. In service environments, data-driven tools such as Tekmetric’s reliable digital vehicle inspection solution help translate inspection data into clear, visual reports that improve transparency, customer trust, and service approval rates.

This builds loyalty and improves satisfaction.

Some practical applications include:

- Predictive alerts for upcoming maintenance or part replacement.

- Customized car media experience based on user preferences.

- Targeted marketing campaigns aligned with customer habits and ownership history.

6. Dealer Network and Sales Optimization

Dealerships are increasingly using analytics to transform their business models from reactive selling to proactive engagement. With access to real-time data, dealers can optimize pricing strategies, monitor sales performance, and predict customer churn with greater accuracy.

Examples of application include:

- Dynamic pricing tools that adjust based on demand and inventory.

- Churn prediction models to retain at-risk customers through targeted offers.

- Performance dashboards that benchmark dealer output across regions.

By adopting these practices, dealer networks strengthen, increase profits, and retain customers while staying aligned with market demand.

7. Connected and Autonomous Vehicles

Connected and autonomous vehicles represent one of the most data-intensive areas of the automotive industry. These vehicles rely on advanced analytics to process streams from LiDAR, radar, and cameras, supporting instant decisions for navigation, safety, and traffic optimization. Without robust analytics, such vehicles cannot function reliably in complex environments.

Key applications include:

- Real-time safety: instant hazard recognition from sensor data.

- Traffic optimization: rerouting based on congestion or weather conditions.

- Sensor fusion: combining data from multiple inputs to create a 360° awareness.

Analytics thus forms the backbone of autonomous driving systems, turning raw data into actionable intelligence for safe and efficient mobility.

| Application | Key Points |

|---|---|

| Manufacturing Optimization | AI defect detection, faster production, lower warranty costs |

| Supply Chain & Inventory | Demand forecasting, leaner stock, lower holding costs, agile recovery |

| Predictive Maintenance | Sensor-based monitoring, reduced downtime, lower repair costs, longer vehicle life |

| Customer Experience | Personalized services, predictive alerts, custom infotainment, targeted offers |

| Dealer Network Optimization | Dynamic pricing, churn prediction, sales dashboards, higher profitability |

| Connected & Autonomous Vehicles | Real-time hazard detection, traffic optimization, sensor fusion, safe driving |

Stay Ahead with Data Analytics in the Automotive Industry.

Partner with Kanerika to implement AI-driven solutions for smarter operations.

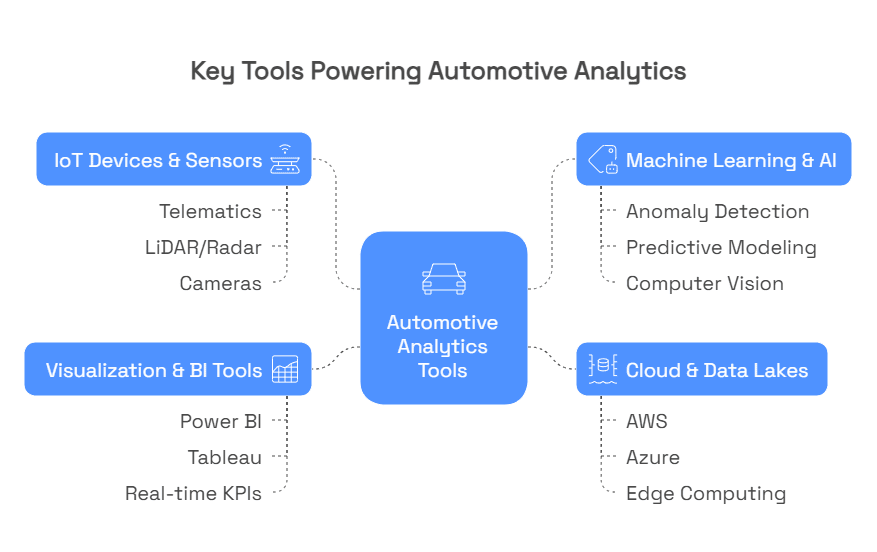

Tools and Technologies Behind Automotive Analytics

1. IoT Devices and Vehicle Sensors

Connected cars gather vast datasets through:

- Telematics units monitor vehicle systems and location.

- OBD (on-board diagnostics) captures engine health, fault codes, and performance metrics.

- LiDAR, radar, and cameras enable depth perception, obstacle detection, and environmental sensing.

Together, these sensors feed the analytics pipelines that power everything from safety systems to predictive maintenance.

2. Machine Learning and AI Models

The engine behind analytics, ML algorithms handle:

- Anomaly detection involves identifying outliers or early signs of defects.

- Predictive modeling, forecasting failures or demand shifts.

- Computer vision enables high-precision visual inspection in factories using AI cameras.

New research indicates that utilizing synthetic images can enhance defect detection by 67%, even with limited real-world data. Deep learning automatically detects defects in cast parts with 94% accuracy in real time.

3. Cloud Platforms and Data Lakes

To manage and analyze massive data volumes, automakers deploy:

- Scalable cloud platforms (AWS, Azure, or private clouds).

- Data lakes aggregating manufacturing, sensor, and CRM data centrally.

- Edge computing, which processes data close to its source (e.g., inside a vehicle), reduces latency and bandwidth requirements.

Cloud infrastructure ensures global access, collaboration, and high-performance analytics for R&D, manufacturing, and customer service.

4. Big Data Visualization & BI Tools

Insights only matter when they’re actionable:

- Tableau, Power BI, and custom-built dashboards help stakeholders visualize performance across vehicles, factories, and dealerships.

- Executives, engineers, and analysts can monitor real-time KPIs—such as defect rates, uptime, or customer trends—via intuitive dashboards.

- Visualization tools democratize data insights, turning complex analytics into clear decision-making support.

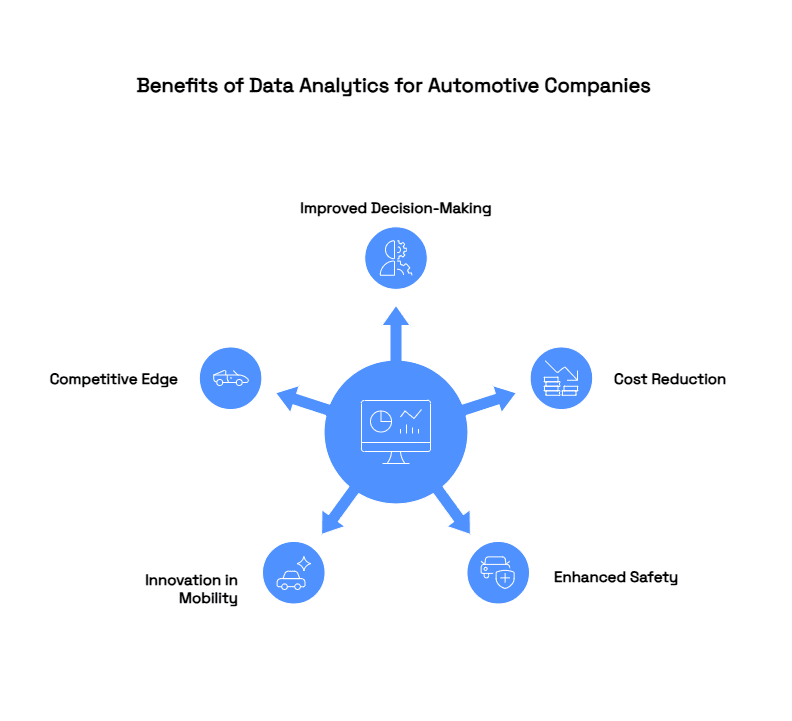

Benefits of Data Analytics for Automotive Companies

1. Improved Decision-Making

AI and machine learning help teams act on real-time data. This leads to faster decisions in design, production, and customer service.

2. Cost Reduction and Operational Efficiency

Predictive maintenance and process optimization reduce downtime and waste. Companies save millions by avoiding breakdowns and streamlining operations.

3. Enhanced Safety and Compliance

Analytics supports driver monitoring, emissions tracking, and regulatory reporting. It helps meet safety standards and avoid penalties.

4. Innovation in New Mobility Models

Data helps manage EV performance, charging networks, and shared mobility platforms. It supports faster adoption and better user experiences.

5. Gaining Competitive Edge in the Global Market

Analytics improves pricing, product launches, and customer retention. Companies using data stay ahead in a fast-moving market.

Case Study: Revolutionizing Telemetric Data for a Connected Mobility Platform

Client Overview

The client operates a telemetry analysis platform serving automotive OEMs, EV manufacturers, insurance providers, and government agencies. Their platform enables smart connectivity and mobility services, generating high-volume telemetry data for fleet management, safety, and operational insights.

Challenge

The client’s default device message structure created integration issues. Binary data from dataloggers had to be converted into a proprietary format; however, customers required these messages in their own specific formats. This mismatch led to delays, dissatisfaction, and operational inefficiencies.

Kanerika’s Solution

Kanerika deployed its low-code platform FLIP to deliver a tailored message translation solution. FLIP enabled seamless conversion of JSON, Excel, and Kafka messages into diverse customer-specific formats. The platform also enriched analytics tools with personalized message transformation logic, improving data flow and business insights.

Impact

- 24% reduction in data integration time

- 27% improvement in operational efficiency

- 16% increase in customer satisfaction

- Significant cost savings by eliminating custom implementation changes that previously averaged $80 per change

Kanerika’s Approach to Data Analytics in the Automotive Industry

Kanerika helps automotive companies turn fragmented data into unified, scalable ecosystems. As a certified Microsoft Data & AI Solutions partner and strategic collaborator with Databricks, we specialize in building modern architectures like data mesh and lakehouse platforms. Our solutions support real-time decision-making across production, supply chain, and dealer networks.

Using tools like Microsoft Fabric, Azure Synapse, and Databricks Lakehouse, we break down silos and enable predictive analytics, quality control, and inventory optimization. Whether you’re starting your data journey or scaling a decentralized setup, Kanerika combines strategic consulting with deep technical delivery to ensure your data flows efficiently and drives tangible results.

Partner with Kanerika to harness data analytics in the automotive industry and drive measurable business outcomes.

Revolutionize Automotive Operations With Data Analytics.

Partner with Kanerika to unlock AI-powered insights for your business.

FAQs

What are the different types of automotive data?

Automotive data includes vehicle performance, driver behavior, telematics, maintenance records, and environmental data, all used to enhance safety, efficiency, and user experience.

What is automotive data analytics?

Automotive data analytics involves collecting and analyzing data from vehicles, sensors, and connected systems to gain actionable insights. These insights help improve vehicle design, enhance safety, optimize performance, reduce costs, and elevate customer experiences.

How is data analytics used in vehicle manufacturing?

In manufacturing, data analytics supports predictive maintenance, identifies defects early, and optimizes supply chains. It also guides engineers in refining vehicle designs for better efficiency, safety, and performance, ensuring higher-quality production.

What role does data analytics play in autonomous vehicles?

Autonomous vehicles rely on analytics to process data from cameras, LiDAR, radar, and GPS. This enables real-time decision-making, obstacle detection, and adaptive driving, ensuring safer and more reliable self-driving operations.

How do automotive companies use analytics for customer experience?

Analytics helps companies personalize infotainment, develop tailored maintenance plans, and provide targeted service recommendations. This enhances convenience, satisfaction, and loyalty for vehicle owners.

Can data analytics reduce vehicle costs?

Yes. Predicting component failures, optimizing maintenance schedules, and improving operational efficiency lower both manufacturing and ownership costs, while also minimizing recalls and warranty claims.