Have you wondered how leading supply chain teams keep goods moving even when unexpected delays, spikes in demand, or route issues arise? A significant reason is the growing use of intelligent automation.

Walmart has recently added battery-free IoT sensors across thousands of stores and distribution centers to track pallets and stock in real-time, thereby improving replenishment and reducing manual labor. Furthermore, DHL also shared that its AI-driven automation system reduced delivery delays by 20% while lowering operational costs, showing how smart systems can transform daily operations.

Global trends support this shift. The AI market in the supply chain sector is expected to reach $9.94 billion by 2025 and may grow to $192.51 billion by 2034. Moreover, logistics automation is also expanding, growing from $67.7 billion in 2025 to $194.7 billion by 2034. These numbers indicate that companies are investing heavily in tools that provide them with faster insights, better tracking, and fewer disruptions.

In this blog, you will learn how intelligent automation works, why it matters, and how it helps supply chains stay faster, sharper, and more dependable.

Transform Your Supply Chain With Intelligent Automation For Faster, Smarter Operations.

Partner With Kanerika To Unlock Seamless Efficiency And End-To-End Visibility.

Key Highlights

- Intelligent automation is transforming supply chains by improving speed, accuracy, and real-time visibility.

- Global investment in AI and automation is rapidly increasing, driven by demand for faster and more reliable logistics.

- Intelligent automation combines AI, RPA, IoT, and cloud tools to optimize tasks like tracking, forecasting, and order fulfillment.

- Key benefits include cost reduction, higher efficiency, better decision-making, and improved customer experience.

- Companies face challenges such as legacy system integration, high implementation costs, and data quality issues.

- Real-world examples from Walmart, DHL, JD Logistics, GXO, and others show measurable gains in efficiency and accuracy.

- Kanerika enables businesses to modernise supply chains with AI-driven automation, predictive insights, and end-to-end optimisation.

What Is Intelligent Automation in Supply Chain?

Intelligent automation in supply chain refers to the use of advanced technologies such as artificial intelligence, machine learning, robotic process automation (RPA), and IoT to automate routine and complex supply chain tasks. Additionally, unlike traditional automation, which only handles repetitive manual processes, intelligent automation combines AI-driven decision-making with automated workflows to optimize logistics, procurement, inventory management, and demand forecasting.

By implementing intelligent automation, businesses can achieve real-time visibility, improve operational efficiency, reduce human errors, and enhance supply chain agility. As a result, companies benefit from faster decision-making, better resource allocation, and cost savings, making it a strategic investment for modern supply chain management.

Intelligent automation is not limited to large enterprises. In fact, even mid-size and small businesses can leverage cloud-based platforms and AI-powered tools to streamline operations, reduce operational costs, and scale efficiently.

Common Use Cases of Intelligent Automation in Supply Chain

1. Automated Inventory Tracking

Intelligent automation utilizes sensors, RFID tags, and AI-driven systems to monitor stock levels in real-time. It can automatically trigger replenishment when inventory falls below a threshold, reducing stockouts and overstock situations. This ensures optimal inventory levels without manual intervention.

2. Predictive Demand Forecasting

AI models analyze historical sales data, seasonal trends, and external factors like market conditions or weather patterns to predict future demand. This helps businesses plan production and procurement more accurately, minimizing waste and improving customer satisfaction.

3. Order Processing Automation

Automation speeds up order validation, invoicing, and fulfillment by integrating ERP systems with AI bots. This reduces human errors, shortens processing time, and ensures faster delivery to customers, improving overall operational efficiency.

4. Supplier Risk Assessment

Intelligent automation aggregates real-time data from multiple sources, such as supplier performance, geopolitical risks, and financial health, to assess supplier reliability. This enables proactive risk management, helping businesses avoid disruptions in their supply chains.

5. Smart Logistics and Route Optimization

IoT sensors combined with AI analytics optimize delivery routes based on traffic, weather, and fuel efficiency. This reduces transportation costs, improves delivery times, and lowers carbon emissions, making logistics smarter and more sustainable.

Tools and Technologies Supporting Intelligent Automation

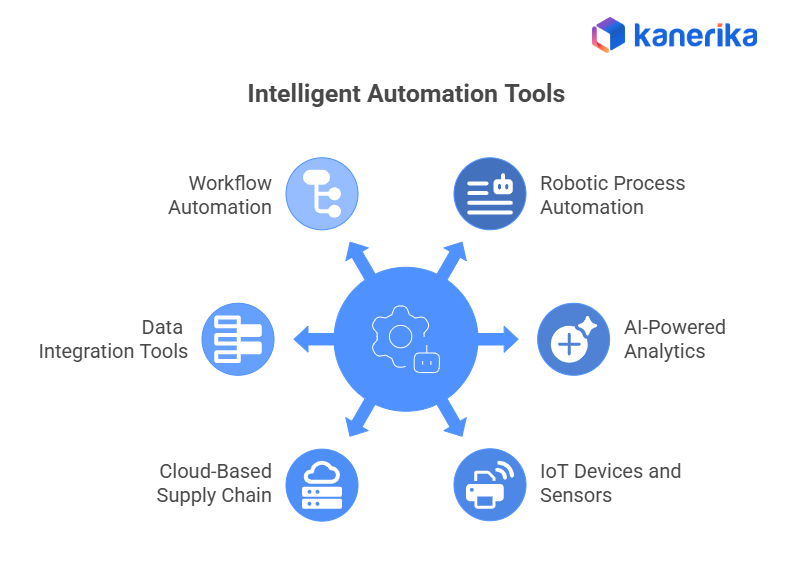

Successful intelligent automation relies on the proper set of tools and technologies that streamline processes, manage data, and provide actionable insights. Furthermore, these tools enable businesses to implement end-to-end automation from procurement to delivery while maintaining visibility and control.

1. Robotic Process Automation (RPA)

RPA helps automate repetitive and rule-based tasks such as invoice processing, purchase order creation, and inventory updates. Consequently, by reducing manual errors, employees are freed to focus on strategic initiatives and higher-value activities.

2. AI-Powered Analytics Platforms

AI-driven platforms, such as Power BI, Tableau, and Azure Synapse Analytics, provide predictive insights, demand forecasting, and real-time monitoring of supply chain performance. Moreover, these tools help businesses make data-driven decisions and optimize operations across the supply chain.

3. IoT Devices and Sensors

IoT devices and sensors enable real-time tracking of goods, equipment, and shipments. Additionally, they also support warehouse automation, predictive maintenance, and improved logistics planning, ensuring timely delivery and reducing operational disruptions.

4. Cloud-Based Supply Chain Management Software

Cloud platforms such as SAP Integrated Business Planning, Oracle SCM Cloud, and Microsoft Dynamics 365 offer integrated and scalable solutions. Furthermore, they allow businesses to centralize operations, improve collaboration across departments, and automate workflows in a secure cloud environment.

5. Data Integration and ETL Tools

Tools like Azure Data Factory, Informatica, and Talend help extract, transform, and load data from multiple sources into a unified system. As a result, clean and consistent data ensures accurate AI predictions and seamless automation across the supply chain.

6. Workflow and Process Automation Tools

Workflow platforms such as Microsoft Power Automate enable organizations to create automated processes that integrate with existing enterprise systems, including ERP and CRM. Consequently, this ensures smoother operations, faster approvals, and improved efficiency across business functions.

By leveraging these tools, organizations can achieve faster operations, enhanced visibility, cost savings, and improved decision-making. In summary, combining automation with AI, IoT, and cloud technologies creates a smarter, more agile, and future-ready supply chain.

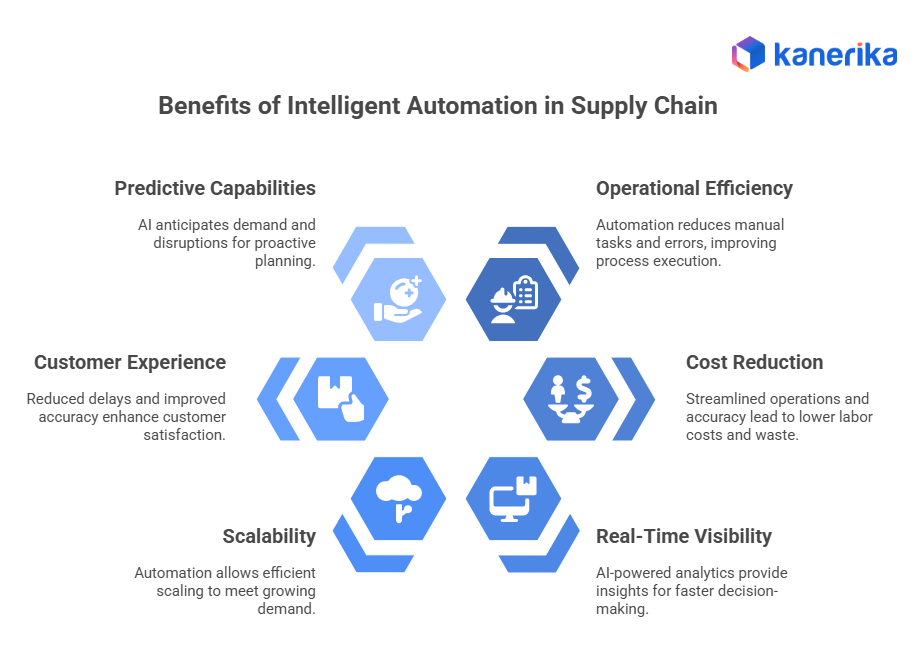

What Are the Main Benefits of Intelligent Automation in Supply Chains?

Intelligent automation in supply chains delivers tangible and measurable benefits that help businesses improve efficiency, reduce costs, and stay competitive. Moreover, by combining AI, RPA, IoT, and cloud-based tools, organizations can optimize every stage of their supply chain, from procurement to delivery.

1. Operational Efficiency and Accuracy

Automation reduces manual tasks, minimizes errors, and ensures consistent execution of processes such as order processing, inventory updates, and logistics tracking. Therefore, this allows teams to focus on strategic decision-making rather than repetitive tasks.

2. Cost Reduction and Resource Optimization

By streamlining operations and improving accuracy, businesses save on labor costs, reduce waste, and optimize inventory levels. Additionally, intelligent automation also lowers the cost of errors and delays, improving overall supply chain profitability.

3. Real-Time Visibility and Faster Decision-Making

With automated data collection and AI-powered analytics, supply chain managers gain real-time insights into inventory, shipments, and supplier performance. As a result, this enables faster decision-making, more accurate forecasting, and improved responsiveness to market changes.

4. Scalability and Flexibility

Automation allows supply chains to scale efficiently to meet growing demand without proportionally increasing resources. Furthermore, businesses can quickly adjust to seasonal fluctuations, market trends, or unexpected disruptions.

5. Enhanced Customer Experience

By reducing delays, improving order accuracy, and providing timely updates, intelligent automation enhances customer satisfaction and builds trust. Consequently, businesses can respond to customer needs more quickly and reliably.

6. Predictive Capabilities

AI-driven predictive analytics helps anticipate demand, prevent stockouts, and identify potential disruptions before they impact operations. Therefore, this supports proactive planning and risk mitigation.

What Challenges Do Companies Face When Implementing Intelligent Automation?

While intelligent automation offers significant benefits, implementing it in supply chains comes with several challenges that require careful planning.

1. Legacy System Integration

Many companies rely on outdated ERP or database systems that may not integrate seamlessly with modern automation tools. As a result, migrating data and aligning processes can be a complex and time-consuming process.

2. High Implementation Costs

The initial investment in AI platforms, RPA tools, IoT devices, and training can be significant. Therefore, organizations need to carefully evaluate ROI and prioritize automation in high-impact areas.

3. Employee Adoption and Training

Automation often changes workflows and job responsibilities. Consequently, employees may resist adopting new tools or lack the necessary skills, making training and change management essential.

4. Data Quality and Consistency

Automation depends on accurate, clean, and well-structured data. Moreover, poor-quality data can lead to errors in predictive analytics, reporting, and automated processes.

5. Cybersecurity and Compliance Risks

Automated systems handling sensitive supply chain data must comply with regulations and be protected against cyber threats. Therefore, companies must implement strong security and governance frameworks.

6. Process Standardization

For automation to be effective, supply chain processes must be standardized and streamlined. In fact, disorganized or inconsistent workflows can reduce the efficiency and impact of automation initiatives.

The Ultimate Guide to Intelligent Automation: Strategies for Digital Transformation

Empower Your Business With AI-Driven Automation, Streamline Workflows And Scale With Kanerika.

Real‑World Case Studies of Intelligent Automation in Supply Chain

Here are some real‑world case studies showing how intelligent automation is being used in supply chains — with practical examples and outcomes:

1. JD Logistics – AI‑Driven Planning and Cost Optimisation

JD Logistics used its “Intelligent Planning Tower” to run AI modelling and real‑scenario simulations for its warehouses and transportation network. As a result, they achieved a 6.71% drop in total logistics costs, boosted delivery efficiency by 28.6%, and reduced transportation distance by 51.5%.

2. GXO – Automated Inventory Counting

Logistics company GXO uses computer vision and AI to scan up to 10,000 pallets per hour, giving real‑time inventory counts and drastically reducing the need for manual stock-taking. Consequently, this has significantly improved accuracy and reduced labor costs.

3. Poloplast – Demand Forecasting with AI

Poloplast, a manufacturer, moved to Microsoft’s Dynamics 365 Supply Chain Management. Furthermore, with AI-driven demand planning, they gained more precise forecasting and eliminated siloed systems, enabling a more connected and accurate supply chain.

4. Global Logistics Provider (ThinkOwl + Odyssey Logistics)

Odyssey Logistics automated its customer service and case‑management operations using ThinkOwl’s AI tools. Moreover, by analyzing business data (such as BOL and PRO numbers) from emails, the system intelligently routes cases, improves data accuracy, and speeds up responses — all of which enhance customer experience and operational efficiency.

5. Goodaymart – Smart Warehousing with IoT

Goodaymart implemented intelligent devices and automation across its warehouse operations. Additionally, their system replaced manual warehouse location tracking with an “intelligent shelf guidance” system, resulting in 99.99% inventory accuracy.

6. Vecna Robotics – Autonomous Robotics in Warehouses

Vecna Robotics’ automated material‑handling robots (like tuggers and lifters) are used to boost fulfillment speed in distribution centers. For example, FedEx has used Vecna’s tuggers to pull carts, reducing walking distances and improving efficiency.

AI in Supply Chain 2025: Optimizing Logistics & Inventory

AI-powered forecasting, logistics & inventory optimization to make supply chains more agile.

FLIP: Kanerika’s AI-Powered Intelligent Automation Platform

FLIP is Kanerika’s AI-powered platform built to simplify and automate complex business processes. It uses low-code and no-code tools so teams can create workflows without heavy technical effort. It’s an AI-powered, low-code/no-code DataOps platform that enables organizations to manage, transform, and analyze data without heavy technical effort.

What Makes FLIP Unique?

- Enterprise Security: Robust compliance and security protocols for sensitive data across hybrid environments.

- Low-Code/No-Code Simplicity: Build workflows using drag-and-drop tools, making automation accessible to non-technical teams.

- AI and Generative AI Integration: Use AI agents and LLM-powered models for smart data analysis, instant insights, and predictive decision-making.

- DataOps Capabilities: Handle ingestion, transformation, validation, and orchestration of structured and unstructured data efficiently.

- Pre-Built Connectors: Integrate with ERP, CRM, cloud platforms, and legacy systems for seamless automation.

- Real-Time Automation: Monitor pipelines, detect anomalies, and trigger alerts for faster response.

The platform is designed for scalability. Companies can start with a few processes and expand automation as they grow and mature. FLIP works across various industries, including supply chain, finance, healthcare, and retail. It helps reduce operational costs, improve data accuracy, and accelerate decision-making.

Kanerika: Powering Supply Chains with Intelligent Automation

Supply chains today need speed, accuracy, and flexibility. Kanerika helps businesses achieve this through intelligent automation. Furthermore, we combine AI, machine learning, and robotic process automation to remove inefficiencies and make operations smarter. Our solutions reduce manual work, cut errors, and improve responsiveness to market changes.

We use AI-driven insights to optimize every stage of the supply chain. Moreover, from demand forecasting to route planning, our automation tools ensure better inventory control and timely deliveries. Businesses gain the ability to predict trends, manage supplier relationships, and respond quickly to disruptions. As a result, this leads to lower costs, fewer delays, and improved customer satisfaction.

Kanerika goes beyond deploying technology. In fact, we provide an end-to-end support strategy, implementation, and continuous optimization so automation becomes a natural part of your operations. With our expertise in RPA, AI, ML, and NLP, we deliver solutions tailored to your business needs and scale with your growth. Therefore, the result is a supply chain that is efficient, resilient, and ready for the future.

Streamline Processes And Eliminate Bottlenecks Using Intelligent Automation.

Work With Kanerika To Build A High-Performing, Digitally Empowered Supply Chain.

FAQs

What is intelligent automation in supply chain?

Intelligent automation in supply chain uses artificial intelligence, robotics, and smart software to automate routine and complex tasks, streamline operations, and improve overall supply chain efficiency.

How does intelligent automation improve supply chain efficiency?

It reduces manual effort, minimizes human errors, accelerates processing times, improves demand forecasting, optimizes inventory, and ensures faster and more accurate order fulfillment.

Which supply chain processes benefit most from intelligent automation?

Processes such as procurement, warehouse management, inventory tracking, order processing, logistics planning, and predictive maintenance see the greatest impact from automation technologies.

Is intelligent automation expensive to implement in supply chains?

While initial investment in software, robotics, and integration can be significant, the long-term benefits include lower operational costs, higher accuracy, faster delivery, and improved customer satisfaction.

How can businesses start adopting intelligent automation in their supply chain?

Businesses can start by mapping their existing processes, identifying repetitive and high-volume tasks, selecting appropriate automation tools, implementing solutions gradually, and training teams to manage and optimize the automated systems.