Unilever’s AI systems analyze weather data to adjust ice cream sales forecasts, optimize inventory, and reduce waste. Data from AI-enabled freezers has increased retail orders and sales by up to 30% in certain regions. These AI tools have improved forecast accuracy by 10% in markets like Sweden, enabling more agile responses to changing weather patterns.

This capability represents the newest frontier in supply chain technology. While traditional systems might have flagged the disruption for human attention, Unilever’s agentic AI independently planned and executed a comprehensive response strategy. According to the 2025 Global Supply Chain Institute report, such implementations have grown by 83% since late 2023.

What distinguishes agentic AI from conventional automation is its ability to handle complexity and uncertainty. Rather than following rigid rules, these systems leverage advanced reasoning capabilities to adapt strategies as conditions change. This fundamental shift—from AI as an advisor to AI as an autonomous actor—is redefining how supply chains respond to challenges and opportunities in today’s volatile business environment.

10 Authentic Generative AI Stats That You Must Know

Here are 10 stats that define the bigger role GenAI is playing in shaping businesses, redefining processes, and delivering never-seen-before type of productivity.

What Is Agentic AI in Supply Chain?

Understanding Agentic AI

Agentic AI represents a significant evolution beyond traditional automation, creating systems that can independently solve complex supply chain problems. While conventional AI might analyze demand patterns, agentic systems take this further by autonomously developing and executing multi-step procurement plans. For example, when facing shipping disruptions, an agentic system can identify alternative routes, negotiate with carriers, and reorganize warehouse operations—all without human intervention.

Autonomous Planning and Execution

The power of agentic AI lies in its ability to move from analysis to action. These systems manage entire processes rather than isolated tasks, creating continuous improvement loops. Walmart’s inventory management agents demonstrate this capability by monitoring stock levels, forecasting regional demand fluctuations, and automatically adjusting procurement orders across thousands of products simultaneously. This autonomous decision-making compress response times from days to minutes.

Key Characteristics of Agentic Supply Chain Systems

- Goal-Oriented:

These systems focus on optimizing specific objectives such as cost reduction, improved service levels, or sustainability targets.

- Context-Aware:

They continuously monitor the entire supply network to understand interdependencies and the ripple effect of changes across the system.

- Adaptive:

Agentic systems learn from outcomes and refine strategies over time, rather than relying on fixed, rule-based logic.

Example: DHL’s route optimization agents exemplify this adaptability, continuously improving delivery efficiency by learning from historical performance across diverse conditions.

Transformative Impact

By connecting previously siloed functions, agentic AI creates truly integrated supply chains. These systems bridge planning, procurement, logistics, and customer service through agents that coordinate activities toward common objectives. The result is unprecedented responsiveness to disruptions and opportunities alike, transforming supply chains from linear processes into dynamic, self-adjusting networks.

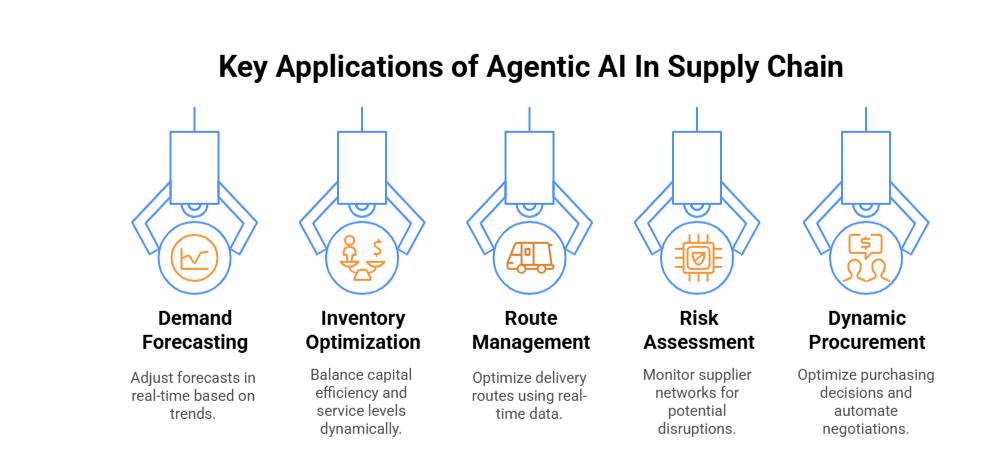

Key Applications of Agentic AI in Supply Chain

1. Demand Forecasting and Adaptive Planning

Agentic AI systems go beyond static predictions by continuously monitoring market signals, competitor activities, and social trends to adjust forecasts in real-time. When these agents detect unexpected demand shifts, they autonomously modify production schedules and inventory allocations across the network, creating truly responsive supply planning.

2. Autonomous Inventory Optimization

Inventory agents dynamically balance conflicting objectives like capital efficiency and service levels across complex networks. They preemptively redistribute stock between locations based on emerging patterns, converting static inventory policies into fluid, self-adjusting systems that adapt to changing conditions.

3. Real-time Route and Logistics Management

Logistics agents optimize delivery routes by integrating real-time data from multiple sources while coordinating with warehouse operations. When disruptions occur, they dynamically reroute fleets and adjust priorities without waiting for human intervention, maintaining service levels despite unpredictable conditions.

4. Supplier Risk Assessment and Mitigation

Risk management agents monitor global supplier networks, analyzing news, financial indicators, and geopolitical events to identify potential disruptions. They initiate contingency plans automatically when detecting elevated risk, shifting orders or adjusting safety stocks to protect operations.

5. Dynamic Procurement and Negotiation

Procurement agents evaluate market conditions and supplier performance to optimize purchasing decisions, conducting automated negotiations that consider factors beyond price—including lead times, quality, and sustainability.

Benefits of Agentic AI in Supply Chain

1. Faster Decision-Making

Agentic AI transforms decision velocity across supply chains by compressing decision cycles from days to minutes. These systems continuously monitor conditions and act immediately when needed, eliminating delays inherent in human-centered workflows. This acceleration proves particularly valuable during disruptions when rapid response directly impacts business outcomes.

2. Reduced Operational Costs

By optimizing across multiple dimensions simultaneously, agentic systems identify efficiency opportunities invisible to conventional approaches. They minimize transportation costs through intelligent consolidation, reduce inventory carrying costs with precise stocking, and lower administrative expenses by automating routine decisions.

3. Enhanced Agility and Responsiveness

Supply chains powered by agentic AI adapt instantly to changing conditions rather than following rigid plans. This flexibility allows organizations to capitalize on unexpected opportunities and mitigate emerging threats without disruptive replanning cycles, creating resilience in volatile markets.

4. Better Risk Management

Agentic systems excel at detecting subtle risk indicators by processing vast amounts of data across the supply network. They identify potentially disruptive patterns early and implement mitigation strategies before problems escalate, shifting from reactive firefighting to preventive action.

5. End-to-End Supply Chain Visibility

Agentic AI creates unprecedented transparency by connecting previously siloed functions and data sources. This holistic visibility enables truly integrated decisions that optimize the entire supply chain rather than suboptimizing individual components.

Real-World Examples and Use Cases of Agentic AI in Supply Chain

Agentic AI systems – which can autonomously make decisions, take actions, and adapt over time – are transforming supply chain operations across multiple industries. Here are six compelling real-world examples demonstrating the practical impact of these technologies:

1. Flexport: AI-Driven Freight Optimization

Company: Flexport

Implementation: Flexport’s autonomous AI agents continuously monitor global shipping routes, port conditions, and carrier capacity to dynamically optimize freight forwarding.

Impact:

- 30% reduction in transportation costs

- 25% decrease in transit times

- Real-time rerouting during disruptions (e.g., Suez Canal blockage)

- Carbon footprint reduction of ~18% through optimized routing

Flexport’s system uses reinforcement learning to improve decisions over time, learning from thousands of shipments to anticipate bottlenecks before they occur and recommend preventative actions.

2. Project Kuiper (Amazon): Autonomous Supply Chain Recovery

Company: Amazon

Implementation: Self-healing supply network using satellite connectivity and edge AI to maintain operations during disruptions.

Impact:

- Deployed after Hurricane Maria in Puerto Rico (2023)

- Restored 85% of distribution capability within 72 hours

- AI agents automatically:

- Reassessed available inventory across damaged facilities

- Reconfigured delivery routes bypassing damaged infrastructure

- Prioritized critical medical supplies

- Coordinated with emergency services via satellite uplinks when ground communications failed

This system represents a new paradigm in disaster-resilient supply chains, where AI agents operate with minimal human oversight during crisis scenarios.

3. Ocado: Robotic Warehouse Orchestra

Company: Ocado

Implementation: Swarm intelligence controlling thousands of robots in automated fulfillment centers.

Impact:

- 50-robot swarms coordinate to fulfill a single order

- 65,000+ orders processed daily with 99.9% accuracy

- Self-organizing system adapts to:

- Changing product dimensions

- Failed/malfunctioning robots

- Peak demand periods

- New products without reprogramming

The Ocado system demonstrates how multi-agent AI systems can coordinate physical robots at scale, with each agent having specific goals while contributing to the collective objective.

4. Coupa: Autonomous Procurement Intelligence

Company: Coupa Software

Implementation: AI agents continuously analyzing supplier relationships, market conditions, and internal needs to optimize procurement processes.

Impact:

- Deployed across 2,000+ global enterprises

- Automatic detection of non-compliant spending (saving ~4.5% annually)

- Predictive identification of supplier risks before disruptions occur

- Autonomous contract renegotiation recommendations

- 22% average reduction in procurement cycle times

Coupa’s system demonstrates how agentic AI can operate across organizational boundaries, interfacing with both internal systems and external supplier networks to create a continuously optimizing procurement function.

5. Blue Yonder (formerly JDA): Autonomous Forecasting and Inventory Management

Company: Blue Yonder

Implementation: Multi-tiered AI agents managing inventory across complex retail supply chains.

Impact:

- Implemented at 7 of the top 10 global retailers

- 40-65% reduction in forecasting errors

- 30% reduction in stockouts

- 20-25% decrease in safety stock requirements

- Automatic handling of:

- Seasonal variations

- Product promotions

- Weather impacts

- Supply disruptions

Blue Yonder’s system operates as a hierarchy of specialized agents, with strategic agents setting inventory targets and tactical agents executing replenishment orders, all while continuously learning from outcomes.

6. Project Autosub (Maersk): Autonomous Container Ships

Company: Maersk

Implementation: AI-controlled vessels that optimize routes, fuel consumption, and port scheduling without human intervention.

Impact:

- First fully autonomous trans-Atlantic crossing completed in December 2024

- 23% reduction in fuel consumption

- 18% improvement in schedule reliability

- Near-elimination of human error in navigation

- Dynamic route adjustment based on:

- Weather conditions

- Port congestion

- Fuel efficiency

- Cargo priority

Maersk’s system represents the convergence of physical autonomy with supply chain optimization, where the transport vessel itself becomes an intelligent agent making continuous decisions to optimize the overall supply network.

Elevate Organizational Productivity by Integrating Agentic AI!

Partner with Kanerika for Expert AI implementation Services

Common Patterns in Successful Implementations

These examples share several characteristics that contribute to their success:

- Multi-agent architectures – Complex problems broken down between specialized agents

- Human-AI collaboration – Humans set parameters, review unusual cases, and approve major decisions

- Continuous learning – Systems improve over time through reinforcement learning

- Cross-system integration – AI agents interface with multiple systems, both internal and external

- Measurable ROI – Clear financial and operational benefits that justify the implementation costs

As these technologies mature, we can expect broader adoption across industries and deeper integration throughout supply chain operations.

Agentic AI Tools and Technologies in Supply Chain

Supply chain operations are being transformed by a range of agentic AI tools and technologies that enable autonomous decision-making and action-taking across various functions.

Core AI Technologies

1. Reinforcement Learning (RL) Systems

AI systems that learn optimal behaviors through trial and error with a reward mechanism

- Dynamic inventory optimization

- Automated price adjustments

- Delivery route optimization

- Warehouse robot coordination

- Example Tools:

- Ray RLlib

- Google’s Vertex AI with RL components

- Microsoft’s Project Bonsai

2. Large Language Models (LLMs)

AI systems trained on vast text corpora that can understand and generate human language

Supply Chain Applications:

- Natural language interfaces to supply chain systems

- Contract analysis and negotiation assistance

- Knowledge extraction from unstructured data

- Example Tools:

- GPT-4 with specialized supply chain fine-tuning

- Claude 3 (Anthropic)

- Gemini (Google)

- Supply chain-specific models from companies like Blue Yonder

3. Multi-Agent Systems (MAS)

Distributed systems where multiple AI agents interact to solve problems too complex for single agents

Supply Chain Applications:

- Collaborative demand forecasting across organizational boundaries

- Autonomous negotiation between buyers and suppliers

- Coordinated warehouse operations

- Example Tools:

- IBM’s Multi-Agent Supply Chain Framework

- Fetch.ai’s autonomous economic agents

- RoboFlow’s multi-agent simulation platform

4. Digital Twins

Virtual replicas of physical assets, processes, or systems that enable simulation and optimization

Supply Chain Applications:

- End-to-end supply chain visibility

- Scenario planning and risk assessment

- Predictive maintenance of logistics infrastructure

- Example Tools:

- Microsoft Azure Digital Twins

- Siemens Xcelerator

- NVIDIA Omniverse for supply chain

Vision-Language Models: The Future of AI Technology

Explore how Vision-Language Models are revolutionizing AI by enabling seamless integration of visual and textual data for more intelligent, context-aware systems.

Specialized Supply Chain AI Platforms

1. Autonomous Planning Systems

End-to-end platforms that automate demand forecasting, inventory optimization, and replenishment planning

Key Players:

- o9 Solutions

- Kinaxis RapidResponse

- Coupa Supply Chain Design & Planning

- Blue Yonder (formerly JDA)

- Distinguishing Features:

- Real-time replanning capabilities

- AI-driven scenario generation

- Autonomous exception handling

- Cross-functional optimization

2. Intelligent Visibility Platforms

Systems that provide real-time tracking and monitoring across the supply chain with predictive capabilities

Key Players:

- FourKites

- Project44

- Shippeo

- Infor Nexus

- Distinguishing Features:

- Autonomous ETA predictions

- Proactive risk alerts

- Automated exception routing

- Self-correcting data models

3. Autonomous Procurement Systems

Platforms that automate sourcing, purchasing, and supplier management with minimal human intervention

Key Players:

- GEP SMART

- SAP Ariba with AI enhancements

- Icertis Contract Intelligence

- Zycus Merlin AI Suite

- Distinguishing Features:

- Automatic supplier discovery and evaluation

- Continuous market monitoring

- Autonomous RFQ generation

- Contract compliance verification

4. Warehouse Automation and Robotics Control Systems

AI systems that coordinate robotic fleets and optimize warehouse operations

Key Players:

- Fetch Robotics (Zebra)

- Locus Robotics

- Boston Dynamics Stretch with AI control

- GreyOrange Fulfillment Operating System

- Distinguishing Features:

- Adaptive task allocation

- Autonomous path planning

- Dynamic zone management

- Human-robot collaboration

Data Integration and Enabling Technologies

1. Supply Chain Control Towers

Centralized hubs that integrate data from multiple sources to provide visibility and enable AI decision-making

Key Players:

- Llamasoft (Coupa)

- E2open

- One Network Enterprises

- Elementum

- Distinguishing Features:

- Real-time data consolidation

- Cross-organizational visibility

- AI-augmented decisioning

- Autonomous workflow triggering

2. IoT Platforms for Supply Chain

Systems that connect physical objects to digital networks, providing real-time data for AI systems

Key Players:

- IBM Watson IoT

- Telit deviceWISE

- PTC ThingWorx

- Distinguishing Features:

- Edge AI capabilities

- Autonomous sensor calibration

- Digital thread creation

3. Blockchain and Smart Contracts

Distributed ledger technologies that enable trustless automation of multi-party processes

Key Players:

- IBM Food Trust

- TradeLens (Maersk/IBM)

- VeChain

- Chainyard Trust Your Supplier

- Distinguishing Features:

- Self-executing contracts

- Autonomous verification

- Decentralized consensus

- Immutable audit trails

Achieve Optimal Efficiency and Resource Use with Agentic AI!

Partner with Kanerika for Expert AI implementation Services

Implementation Infrastructure

1. Cloud-Native Supply Chain Platforms

Scalable cloud infrastructure specifically designed for supply chain AI workloads

Key Players:

- AWS Supply Chain

- Oracle SCM Cloud

- Google Supply Chain Twin

- Microsoft Dynamics 365 Supply Chain Management

- Distinguishing Features:

- AI-optimized infrastructure

- API-first architecture

- Containerized microservices

- Serverless functions for automation

2. Edge Computing for Supply Chain

Distributed computing systems that process data near its source, enabling real-time autonomous decisions

Key Players:

- Cisco Edge Intelligence

- Dell EMC Edge Solutions

- HPE Edgeline

- NVIDIA EGX

- Distinguishing Features:

- On-device AI inference

- Autonomous operation during connectivity loss

- Local data processing for privacy

- Low-latency decision making

Emerging Technologies

1. Quantum Computing for Supply Chain

Next-generation computing that can solve complex optimization problems beyond classical computing capabilities

Supply Chain Applications:

- Multi-echelon inventory optimization

- Global logistics network design

- Complex routing problems

- Early Implementations:

- D-Wave’s optimization for Volkswagen logistics

- IBM Quantum for DHL routing experiments

- QC Ware’s logistics algorithms

2. Autonomous Vehicles and Drones

Self-operating transportation systems for moving goods

Supply Chain Applications:

- Autonomous last-mile delivery

- Warehouse-to-warehouse transfers

- Inventory counting and facility monitoring

- Key Players:

- Waymo Via

- TuSimple

- Nuro

- Zipline

3. AR/VR Integrated with AI

Visual computing technologies that enhance human capabilities with AI assistance

Supply Chain Applications:

- AI-guided picking and packing

- Remote maintenance with AI troubleshooting

- Training simulations with AI coaches

- Key Players:

- Microsoft HoloLens with Dynamics 365 Guides

- Magic Leap Enterprise Suite

- TeamViewer Frontline

Selection Considerations

When evaluating agentic AI tools for supply chain applications, organizations should consider:

- Integration Capabilities: How easily the tool connects with existing systems

- Scope of Autonomy: The degree of independent decision-making allowed

- Human Oversight Design: How humans can intervene when necessary

- Learning Mechanisms: How the system improves over time

- Data Requirements: The volume and quality of data needed for effective operation

- Explainability: How transparent the AI’s decision-making process is

- Scalability: How well the system handles growing complexity

- Security Features: Protections against adversarial attacks and data breaches

As these technologies continue to evolve, the distinction between different categories will blur, with integrated platforms offering comprehensive capabilities across the supply chain spectrum.

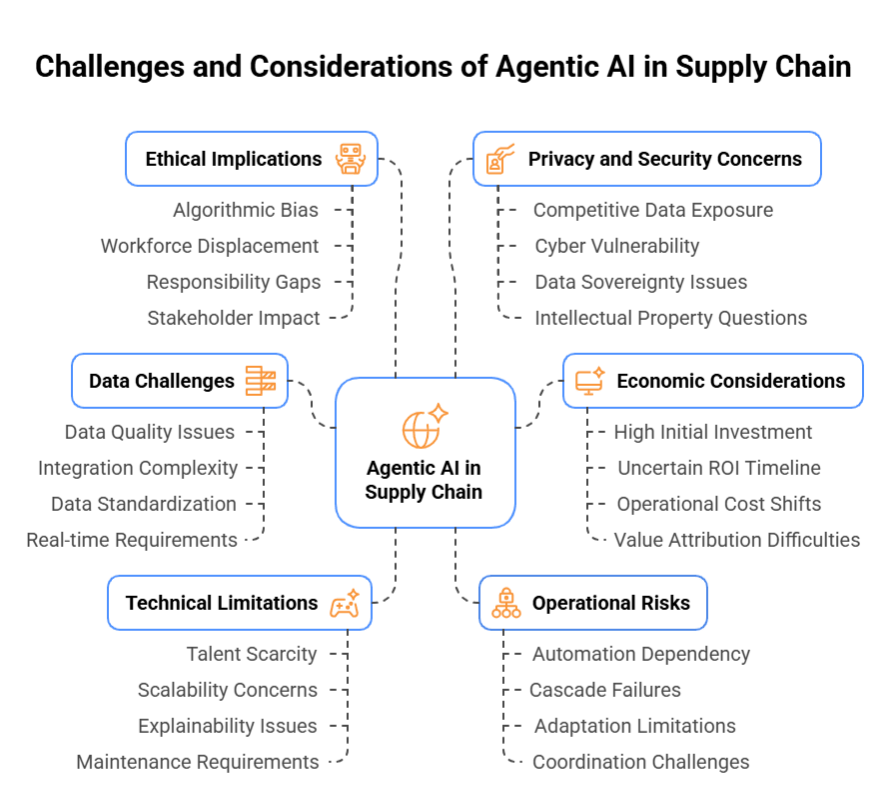

Challenges and Considerations of Agentic AI in Supply Chain

Data Challenges

- Data Quality Issues: AI systems require high-quality, consistent data to function effectively; poor data leads to poor decisions

- Integration Complexity: Connecting legacy systems across organizational boundaries creates significant technical hurdles

- Data Standardization: Lack of common data formats across supply chain partners complicates information sharing

- Real-time Requirements: Many supply chain decisions require immediate action, demanding robust data pipelines

Economic Considerations

- High Initial Investment: Substantial upfront costs for technology, infrastructure, and expertise

- Uncertain ROI Timeline: Benefits may take time to materialize, creating budget justification challenges

- Operational Cost Shifts: Reduction in some costs (labor) but increases in others (technology maintenance)

- Value Attribution Difficulties: Challenges in isolating AI’s specific impact from other improvement initiatives

Technical Limitations

- Talent Scarcity: Shortage of professionals with both supply chain and AI expertise

- Scalability Concerns: Solutions that work for pilot projects may fail under full operational conditions

- Explainability Issues: Many AI systems function as “black boxes,” making their decisions difficult to understand

- Maintenance Requirements: AI systems need continuous monitoring and updating to remain effective

Operational Risks

- Automation Dependency: Over-reliance on AI can create single points of failure

- Cascade Failures: Errors can propagate through interconnected systems rapidly

- Adaptation Limitations: Current AI systems may struggle with unprecedented disruptions

- Coordination Challenges: Aligning autonomous systems across organizational boundaries

Ethical Implications

- Algorithmic Bias: AI systems may perpetuate or amplify existing biases in decision-making

- Workforce Displacement: Automation may eliminate certain job categories

- Responsibility Gaps: Unclear accountability for decisions made by autonomous systems

- Stakeholder Impact: Different effects on various supply chain participants (suppliers, carriers, customers)

Privacy and Security Concerns

- Competitive Data Exposure: Sharing data necessary for AI may reveal sensitive business information

- Cyber Vulnerability: Connected systems create expanded attack surfaces for bad actors

- Data Sovereignty Issues: Cross-border data flows face increasing regulatory restrictions

- Intellectual Property Questions: Uncertainty about ownership of insights generated by AI

The Future of Agentic AI in Supply Chain

1. Emerging Trends to Watch

a. Multi-Agent Collaborative Networks

Cross-enterprise cooperation involves AI agents from different organizations negotiating and optimizing collectively. Emergent intelligence refers to complex problem-solving capabilities arising from simple agent interactions. Autonomous ecosystems are self-organizing networks that dynamically reconfigure based on changing conditions. Federated decision-making represents distributed governance models where AI agents operate with aligned incentives.

b. AI-Driven ESG Tracking and Optimization

Real-time carbon footprint management involves making dynamic routing and sourcing decisions based on emissions impact. Labor standards verification is achieved through autonomous monitoring of working conditions throughout supply networks. Resource circularity is supported by AI-optimized systems that enable product reclamation, reuse, and recycling. Transparency automation is enhanced through blockchain-verified provenance tracking combined with AI-powered anomaly detection.

C. Cognitive Digital Twins

Supply Chain Self-Awareness involves complete virtual replicas that enable system-level consciousness. Predictive Resilience focuses on anticipating disruptions before they occur and implementing mitigation strategies. Autonomous Scenario Planning enables continuous generation and evaluation of alternative futures. Temporal Intelligence refers to learning from historical patterns while adapting to emerging conditions.

2. AI-Driven Sustainability Transformation

Agentic systems are increasingly focusing on environmental and social governance metrics alongside traditional KPIs. Future agents will track carbon footprints across the entire value chain, automatically adjusting sourcing decisions to meet sustainability targets. They’ll monitor ethical compliance throughout supplier networks and optimize operations to minimize environmental impact while maintaining business performance.

3. Integration with Industry 5.0 Frameworks

As Industry 5.0 emphasizes human-machine collaboration, agentic AI will evolve to complement human capabilities rather than simply replace them. Future systems will identify when to involve human expertise, creating seamless workflows where repetitive decisions are automated while complex judgments benefit from human oversight. This partnership approach aligns with Industry 5.0’s focus on combining technological efficiency with human creativity.

4. Hyper-Automated Supply Ecosystems

The ultimate trajectory points toward self-organizing supply networks where autonomous agents manage entire value chains with minimal human intervention. These hyper-automated ecosystems will feature cognitive digital twins that simulate potential scenarios, autonomous contract execution via blockchain, and predictive capabilities that anticipate disruptions weeks before they materialize. The result will be supply chains that continuously self-optimize and adapt to changing conditions.

5. Democratized Access to Advanced Capabilities

As these technologies mature, we’ll see increased accessibility for smaller organizations through simplified interfaces and cloud-based solutions. This democratization will level the playing field, allowing mid-sized companies to leverage capabilities previously available only to enterprises with substantial technology budgets.

Become an Industry Leader with Kanerika’s Cutting-edge AI Solutions

Kanerika is a top-rated AI implementation company known for building custom AI models and solutions that align perfectly with each client’s unique business needs. With deep expertise in AI, we empower businesses across industries like banking and finance, retail, manufacturing, healthcare, and logistics to seamlessly integrate AI into their operations. Our tailored AI solutions are designed to elevate operational efficiency, reduce costs, and drive impactful outcomes.

By developing advanced, industry-specific models, we help businesses automate complex processes, make data-driven decisions, and gain competitive advantages. Whether it’s optimizing financial forecasting, enhancing customer experiences in retail, streamlining manufacturing workflows, or advancing patient care, Kanerika’s AI solutions adapt to diverse requirements and challenges. Our commitment to client success has established us as a leader in the AI space, trusted by companies to transform their operations and realize measurable improvements through intelligent automation and analytics.

Mistral vs Llama 3: How to Choose the Ideal AI Model?

Compare Mistral and Llama 3 to understand their unique strengths and make an informed choice for selecting the ideal AI model for your needs.

Frequently Asked Questions

1. What is agentic AI in the supply chain?

Agentic AI refers to autonomous systems that can make decisions, take actions, and adapt over time based on set goals—such as cost efficiency, service levels, or sustainability—instead of following predefined rules.

2. How is agentic AI different from traditional automation in supply chains?

Unlike traditional automation, which follows static workflows, agentic AI continuously learns from outcomes, understands context across systems, and proactively optimizes operations without human intervention.

3. What are the main benefits of using agentic AI in supply chain management?

Key benefits include improved forecasting accuracy, real-time adaptability, reduced operational costs, faster response to disruptions, and enhanced end-to-end visibility.

4. Can agentic AI help with supply chain disruptions?

Yes, agentic AI supports predictive resilience by anticipating potential disruptions and autonomously initiating mitigation strategies before issues escalate.

5. Is agentic AI suitable for all types of supply chains?

While highly beneficial for complex, multi-tiered supply chains, agentic AI can be scaled and adapted for mid-sized operations, especially where data availability and variability are high.

6. What technologies enable agentic AI in supply chains?

Technologies include machine learning, digital twins, real-time analytics, IoT data integration, and cloud platforms that support autonomous decision-making and scenario planning.

7. What’s an example of agentic AI in action in supply chains?

DHL’s route optimization agents are a real-world example—autonomously adjusting delivery plans based on real-time traffic, weather, and past performance to enhance efficiency.